Scientists from China's Yunnan Normal University investigated the performance of PV-driven cold storage based on an ice thermal storage tank. In these systems, water is frozen during the daytime and used during the night to cool heat transfer fluid, which further cools the products.

“This study combines solar photovoltaic cold storage with phase change thermal energy storage (CTES) technology, focusing on experimental investigations of ice storage and release under the photovoltaic power fluctuations,” said the academics. “Improving the efficiency of photovoltaic cold storage systems and ensuring the quality of agricultural product refrigeration.”

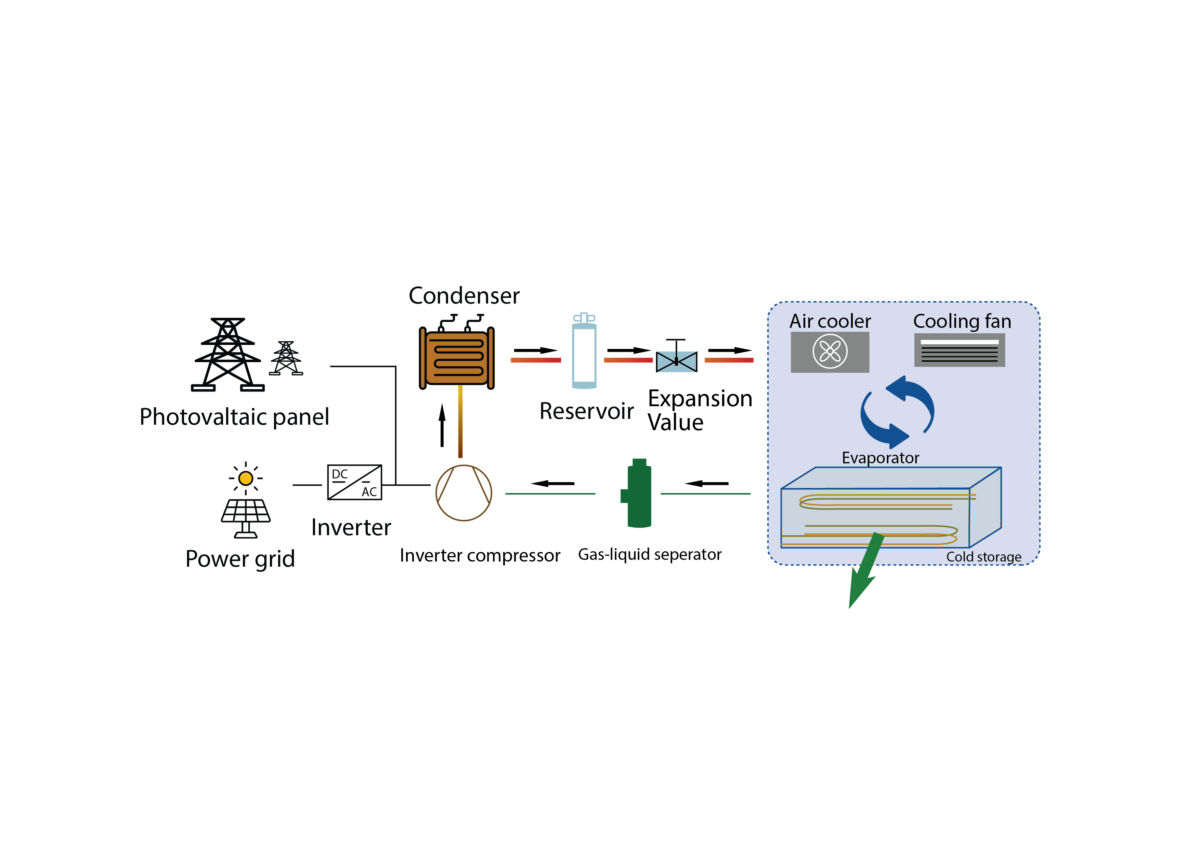

The researchers tested the PV-energized cold storage system in Kunming City, Yunnan Province, China. Electricity was consumed from both the grid and a PV array with a capacity of 5.4 kW. The cold tank could hold 700 kg-800 kg and was placed in a warehouse with a 10 cm polyurethane insulation board.

“There were 32 copper coils in the tank, which divided into two groups: 16 for storing cold and 16 for releasing cold,” the academic group added. “The R22 could flow through the coils for storing cold, absorbing heat from the water, causing the ice to form on the surface of the coil bundle gradually. The other group was for releasing cold, where a 50%-75% ethylene glycol solution flowed through the coils, absorbing heat from the ice.”

In December 2021, the scientists operated the system with no load for five days, while in the following April, they tested it for six days with a load of green grapes. The latter started with a day of pre-cooling, then grape accumulation began on day two, from 414.6 kg to 1,250 kg. The ice storage was carried out for nine hours during the day – from 8:40 to 17:40 – while in the other 15 hours, it melted and cooled the transfer fluid.

“When solar photovoltaic technology was coupled with CTES technology, a 30.20% reduction in annual electricity cost can be achieved,” the results showed. “The refrigeration capacity decreased by 7.15% compared to using CTES technology alone.”

Popular content

Moreover, the average daily ice storage capacity under load decreased by 22.06% compared to the no-load scenario. The refrigeration capacity increased by an average of 45.774% per day. Subcooling—a phenomenon where a substance is cooled below its normal freezing point without freezing—was less than 3 C in the ice storage tank.

“When the thickness of the ice layer outside the coil was within the range of 27-32 mm (with a coil outer diameter of 19 mm), the ice storage performance factor (IPF) reached 35.82%, which could respectively optimize the cooling efficiency of the coil and the cold storage,” the researchers concluded. “To achieve higher cooling efficiency, it is recommended to stop cold thermal energy storage after 72 hours of unloaded operation to avoid complete ice formation, which would cause difficulty in cooling exchange.”

Their results were presented in “Research on the Cold Storage Characteristics of Ice Storage Photovoltaic Cold Storage,” published in Energy and Built Environment.

Another research group at Yunnan Normal University recently developed a direct-drive photovoltaic air conditioning system that can store solar power through ice thermal storage. The performance of this system was evaluated considering operating efficiency and stability and the scientists found that a device relying on a variable-speed compressor and an MPPT controller showed very good ice-making capability.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.