Australia's Griffith University researchers have analyzed the levelized cost of green hydrogen (LCOH) under varying conditions. The study used the case study of a PV or wind turbine (WT) based hydrogen production plant in Queensland, with the basis year of 2030.

“For hydrogen to play its role in the transition to net zero, the cost of production must decrease,” corresponding author, Mostafa Rezaei, told pv magazine. “Our work shows that by increasing the scale from today’s projects powered by a few megawatts of PV to around 1 GW, the cost of producing green hydrogen in Australia by electrolysis of water can fall to $2 per kg before 2050.”

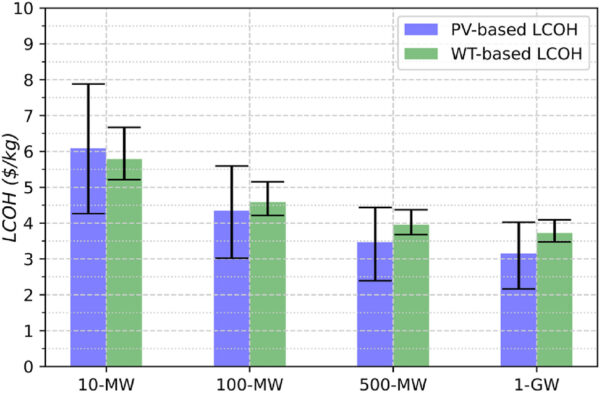

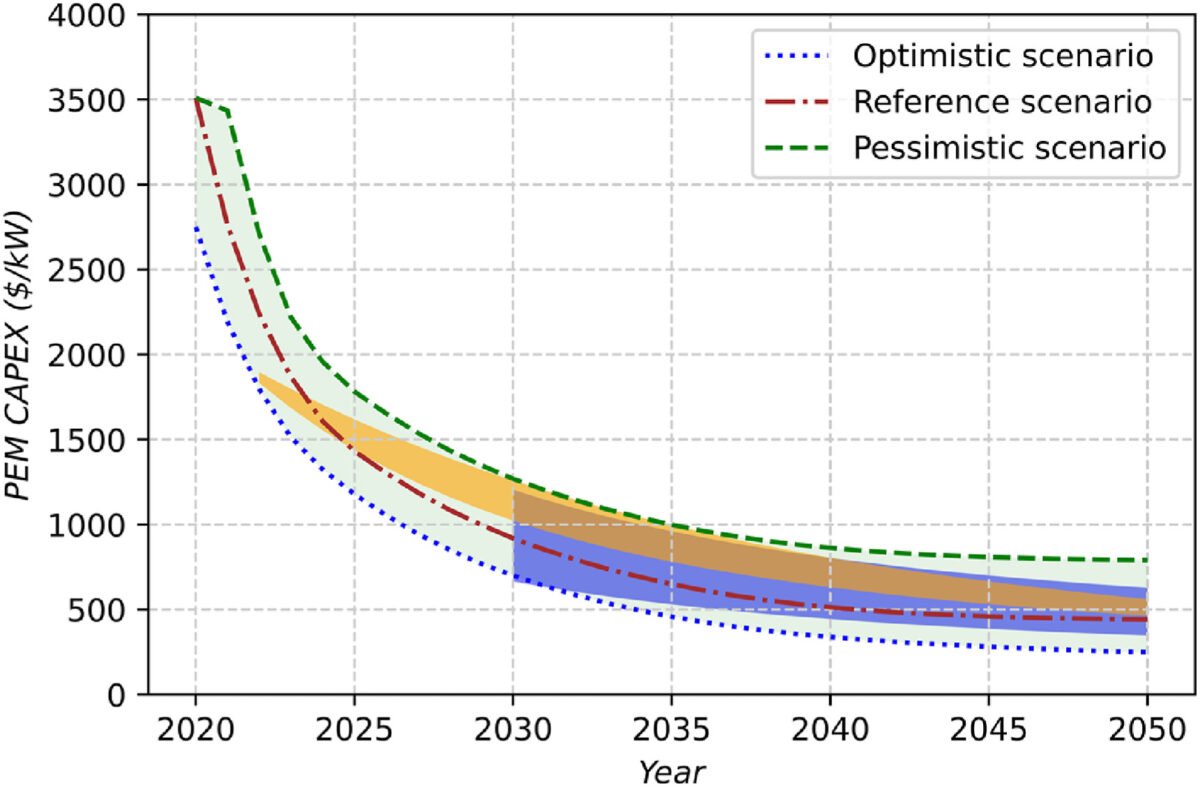

In their study, the researchers assumed a proton-exchange membrane (PEM) as the electrolysis technology for hydrogen production. Solar-based and wind-based power generation plants with 10 MW, 100 MW, 500 MW, and 1 GW installed capacity were assumed to power the electrolyzers.

The varying conditions were regarding the size of the electrolyzer array. In the first variation, it was sized to utilize maximum power at the output of the power generation plant. However, since peak power does not necessarily occur frequently, it might be underutilized. Therefore, the researchers also presented a curtailed power profile, shaving off ineffective peak power, hence enabling a smaller and cheaper electrolyzer array.

A third variation of the array considered the electrolyzer's overloading. “Under this scenario, the electrolyzer is sized to utilize input power exceeding its nameplate capacity infrequently for a short period, to avoid decreasing the stack lifetime,” the researchers explained. “To ascertain the impact on LCOH of incorporating overload capacity, a value of 150% (considering likely improvements until 2030) is assumed.”

Image: Griffith University, Journal of Cleaner Production, CC BY 4.0 DEED

In addition, the study assumed different cost scenarios for 2030. In the optimistic scenario, the installed capex of such a hydrogen plant is AUD 3,061 ($2,017.66)/kg. In the most likely scenario, the installed capex would be AUD 3,586.5/kg; in the pessimistic scenario, it will be AUD 4,132/kg.

Popular content

To calculate the expected LCOH in the different scenarios, the scientists used economic modeling techniques and economics of scale. Their results were presented in “Economics of renewable hydrogen production using wind and solar energy: A case study for Queensland, Australia,” published in the Journal of Cleaner Production.

“Capturing the benefits of economies of scale can significantly lower LCOH to be at or close to the target value of $3/kg H2, regardless of energy source,” they said. By target value, the academics refer to the target for farm-gate cost set by Australia's National Hydrogen Roadmap. Farm-gate cost refers to green hydrogen production only, excluding storage and distribution.

“The simple sizing method for the electrolyzer array (no curtailment and no electrolyzer overload) indicates that only the PV-based LCOH will come close to the target value of $3/kg H2 under the Reference (most likely) scenario for multi-GW projects,” the results showed. “Under the Optimistic scenario, the target value is reached by the PV plant at the scale of over 100 MW.”

In addition, they found that curtailment of 15% for PV achieves an LCOH reduction of about 4% for small-scale plants. Also, the results show that under the Reference scenario, the target LCOH value will be within reach at 1 GW for PV-based plants. The target value is within reach by 2040, they emphasized, even under the pessimistic cost scenario, for PV projects at the 500-MW scale.

“Employing the assumed overload capability of the PEM electrolyzer array (150% for a limited time) achieves a significant decrease in LCOH, such that the target value will be reachable under the Reference scenario for a PV plant size around 1 GW,” they also stated. “Curtailment and overload are effective alternatives, since curtailment shaves the power peaks that could be utilized in overload.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

What is PV-driven green hydrogen