New flexible solar module factory begins operations in the UK

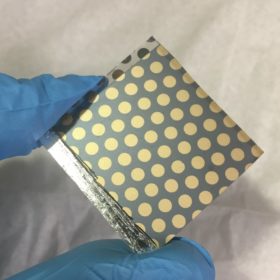

Operated by UK start-up Power Roll, the pilot factory will reach a capacity of 30 MW by year end. The manufacturer uses low-cost roll-to-roll manufacturing processes and patented microgroove patterns to produce flexible solar panels intended for applications on warehouses and agricultural sheds whose roofs are not strong enough for conventional arrays as well as in vehicle-integrated photovoltaics.

Shanghai Electric sounds death knell for CIGS manufacturing project backed by $197m of public money

With five public entities having committed RMB1.25 billion into a project to produce copper, indium, gallium, selenide solar modules five years ago, the joint venture has been abandoned at an estimated impairment cost of RMB1.42 billion.

The weekend read: BIPV no refuge

Deployment in the building integrated PV segment is accelerating, and so too are the number of solar products available to architects and developers. And while BIPV had long been the segment in which an array of thin-film technologies could shine, they are now in increasingly stiff competition with crystalline silicon rivals.

Norwegian investor raises stake in company developing ‘perovskite-boosted’ solar cells

Swedish business Evolar is working on a bolt-on piece of production equipment which would upgrade the cell lines of conventional manufacturers with a perovskite lift in performance.

Rear-side passivation for 17.4% efficient CdTe thin film

Scientists in the United States investigated adding a layer of copper-aluminum oxide to the rear side of a cadmium-telluride thin film cell, finding positive impacts on carrier lifetime and efficiency. With further work, the scientists say, the discovery could open up new routes to higher efficiencies in CdTe solar cells.

Shipping problems for First Solar but production line expansion is under way

The U.S. manufacturer has started building its third Ohio production base and has also begun ordering equipment to kit out its first factory in India.

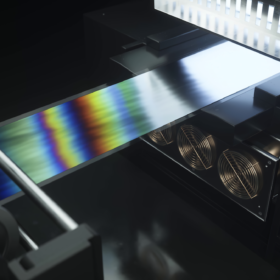

Laser focus on perovskite film formation

Scientists in the United States developed a method to observe the structure and mechanics of a perovskite material during its synthesis and transition from liquid precursors to a solid thin film. The group says its work will provide new insight into manufacturing and the development of reliable large-scale processes for perovskite solar cell production.

Perovskite solar pioneers honored with prestigious prize

The work undertaken separately by seven academics to discover the promise of perovskite materials for solar, and to open the door to high-efficiency devices, has been recognized by the judges of the Rank Prize for Optoelectronics.

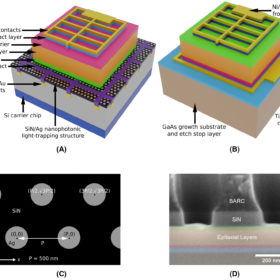

Ultrathin gallium-arsenide solar cell with light management architecture

Scientists led by Cambridge University fabricated an ‘ultrathin’ solar cell, just 80 nanometers thick, using gallium arsenide. The III-V cell achieved 9.08% conversion efficiency, and its developers have demonstrated in simulations that it could reach 16% with further optimization. Given its light weight and intrinsic resistance to radiation, the cell could be suitable to power satellites and other applications in space.

Perovskites can also detect nuclear radiation

Scientists in Switzerland found that perovskites can be used to detect thermal neutrons emitted by radioactive devices. Taking advantage of several properties that also make the materials attractive for solar cell applications, the group was able to fabricate a novel device that could have various practical applications, including in energy generation.