New 400 MW solar module factory for Germany

Production is set to start in the first quarter of next year at the planned fab in Greiz, Thuringia. The facility will manufacture 370 W panels featuring half cells, large wafers and nine busbars.

New method for life cycle assessment of PV technologies

Researchers in Australia have conducted a ‘cradle to grave’ life cycle assessment (LCA) of the four most widely used PV technologies. The academics say that cadmium telluride solar modules have the lowest life cycle impact, followed by amorphous, multi and monocrystalline silicon products.

Jinko launches PV module with record output of 580 W

The panel is part of the company’s new Tiger Pro series, which includes two 530 W modules and a 430 W product for distributed-generation applications. It will begin production of the series in the fourth quarter, although it will start accepting first orders immediately.

PV module recyclers aiming for high-purity material recovery

France’s National Institute for Solar Energy takes a look at the state of play in the European solar panel recycling industry.

Harvesting atmospheric water to cool down PV panels

Scientists from Saudi Arabia have proposed a new PV panel cooling technique which employs an atmospheric water harvester. The device uses waste heat from the PV panel to collect atmospheric water at night and then releases it during the day to cool down the module. The researchers claim the device may also be improved to produce liquid water, which could be used for the cleaning of the modules.

Chinese PV Industry Brief: New capacity expansion plans and 100 MW of PV for a poverty-alleviation project

Three major Chinese PV manufacturers have announced capacity expansion plans over the past week. Chint also released its 2019 financial results, while Kstar unveiled a new inverter supply deal.

A new technique for cooling solar panels

Scientists in Egypt have investigated the effectiveness of using water and a mixture of aluminum oxide and calcium chloride hexahydrate to cool PV modules. Optimal performance was observed with a solution of 75% water, according to the research findings.

Trina secures 105 MW order for its 500 W modules

The Chinese manufacturer will provide Indian developer SunSource Energy with its Vertex panels. Shipments will be made in the fourth quarter.

Chinese manufacturers join forces to build 5 GW module factory

Chinese solar manufacturers Seraphim and Lu’An Solar will invest around $565 million in the new factory.

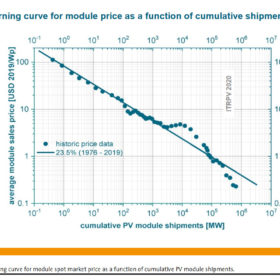

Solar costs set to continue falling according to ITRPV roadmap

The 11th edition of the German document which tracks solar price falls and efficiency improvements has considered the role bigger wafers are playing in cost reduction.