JA Solar, JinkoSolar, Longi reach consensus on 182mm module standardization

The three Chinese panel manufacturers found an agreement on the module size and the mounting hole spacing.

All-perovskite tandem solar cell with 24.9% efficiency via cross-linkable small molecules

Scientists in China found that a change to the hole transport layer material helped to reduce voltage loss in a perovskite solar cell. The discovery demonstrates a promising new pathway to overcoming a major challenge for perovskites – particularly those used as the top layer in a tandem device.

Solar-powered airplane to reach the stratosphere

The airplane is powered by 22 square meters of solar cells with an efficiency of up to 24% and 14 kWh of lithium-ion batteries. According to its creators, it can reach an altitude of 25,000m.

What seawater and salt spray can do to a PV system

Researchers in China have analyzed how the marine environment influences the performance of PV modules deployed on ships, and have found that salt particles can be detrimental to their performance as these act as both heating agents and a factor reducing solar irradiance. The temporary cooling effect provided by seawater is not sufficient to offset the impacts of salt spray and ensure increased power yields.

India may host massive amounts of PV module waste by 2030

India’s solar capacity growth up to 2030 also means the accumulation of a significant amount of PV module waste due to early failures or damage during transportation, installation, and operation. The waste generation could be 21 kilotons, assuming India’s cumulative installed PV capacity grows to 287.4 GW by 2030, from 40 GW in 2020. This doesn’t include end-of-life panel waste, as PV systems installed in the 2020-30 period are assumed to have at least 30 years of lifetime.

Indian coal miner seeks equity partners for 4 GW solar fab

Coal India Ltd. is accepting proposals from parties willing to partner on its proposed 4 GW solar PV ingot-wafer-cell-module manufacturing facility. Applications will be accepted until Sept. 16.

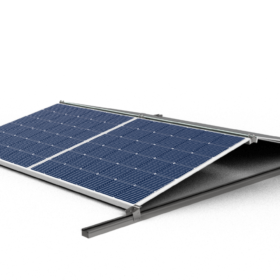

Solar module for east-west installations on flat rooftops

Dutch startup Solarge has developed a 500 W panel that weighs 50% less than conventional glass-backsheet modules. The new product can be fixed to rooftops with roofing anchors, which eliminates the need for ballast, according to the manufacturer.

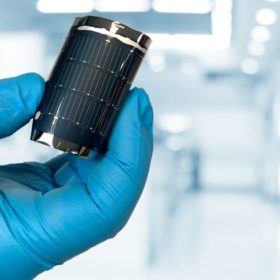

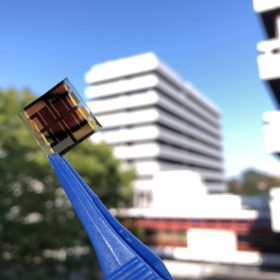

Swiss scientists achieve 21.4% efficiency for flexible CIGS solar cell

The result was confirmed by Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE). The cell was fabricated through a low-temperature co-evaporation method for the growth of the light-absorbing CIGS semiconductor thin film.

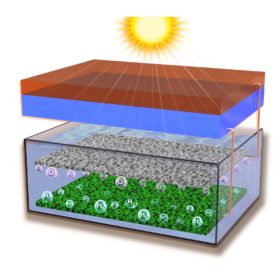

Direct solar hydrogen generation tech powered by 24.3%-efficient tandem perovskite-silicon solar cell

Developed by Australian scientists, the demonstrated system is claimed to achieve a solar-to-hydrogen efficiency of 20% at a levelized cost of hydrogen (LCOH) of $4.10/kg. The direct solar hydrogen generation technology is powered by a tandem perovskite-silicon solar cell with an unprecedented high open-circuit voltage of 1.271 V, and a power conversion efficiency of 24.3%.

Co-evaporated perovskite solar cell with 19.5% efficiency

German scientists have built a perovskite solar cell with spiro-TTB as a hole transport material, via the thermal co-evaporation method. The solar cell has an open-circuit voltage of 1.08 V, a fill factor of 83.0%, and a short-circuit current of 21.6 mA cm.