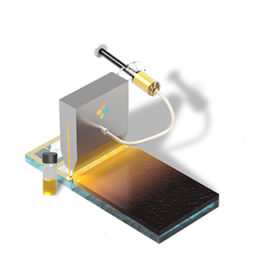

New lab-sized slot die coater for thin film PV

Ossila, a U.K.-based scientific equipment and materials supplier, has launched a new version of its slot die coater for research labs. It is suitable for teams working on thin film photovoltaics at the scaling-feasibility test stage.

European team targets 20%-efficient perovskite modules using industrial processes

The LUMINOSITY project consortium aims to develop 20%-efficient metal halide perovskite prototype modules measuring over 900 cm², designed for a 20-year lifespan and compatibility with roll-to-roll (R2R) processing.

Perovskite solar cell built with slot die coating achieves 19.17% efficiency

A team from Jeonbuk National University in South Korea used slot die coating (SDC) to produce uniform high-quality perovskite films, which they used in a perovskite solar cell that achieved 19.17% efficiency and lab cell-sized modules that achieved 17.42% efficiency.

Danish slot die coating equipment manufacturer raises capital for expansion

Denmark-based slot-die coating equipment manufacturer FOM Technologies raised DKK 43.60 million ($6.3 million) to finance the next stage of growth, which includes expansion of sales in the United States.

Weekend Read: The fruitful search for other thin films

First Solar and its cadmium telluride (CdTe) technology dominate thin-film solar in the mainstream market. Valerie Thompson looks at the US-based business and the future of thin-film PV technology.

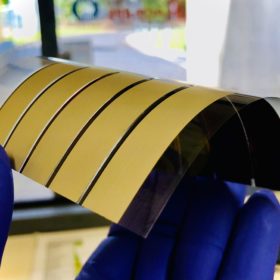

Flexible, roll-to-roll printed perovskite solar cell hits 16.7% efficiency

Australian scientists have demonstrated a flexible perovskite solar cell using roll-to-roll compatible “printing” type processes, which could potentially be applied in large-scale manufacturing. Of particular note is the development of a viable roll-to-roll process to deposit the electrode layer, which has thus far been a major challenge. Cells fabricated by the group achieved a maximum efficiency of 16.7%.

The economics of perovskite solar manufacturing

Scientists in Switzerland put together a detailed analysis of the projected costs of designing and operating a 100 MW perovskite solar cell production line in various locations, taking in labor and energy costs as well as all materials and processing. The found that perovskite PV could be cost-competitive with other technologies even at much smaller scale, but noted that this still depends on the tech proving its long-term stability, and impressive achievements in research being successfully transferred to commercial production.

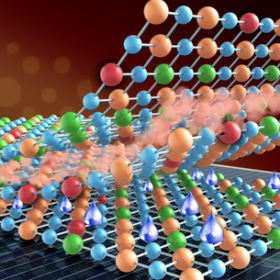

Surface engineering for an 18.6% efficient large-area inverted perovskite solar cell

Scientists in China worked with nickel-oxide as a charge transport layer in a perovskite solar cell, and were able to overcome several of the performance challenges associated with this material through careful surface engineering. Using this approach, the group fabricated an inverted perovskite solar cell measuring 156×156 mm that achieved 18.6% efficiency, along with ‘remarkable’ stability, according to its designers.

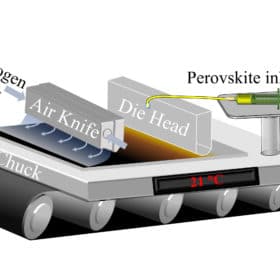

Slot die coating for 20.83% efficient perovskite thin-film solar cell

Scientists in Germany demonstrated a slot die coating process for large-scale production of perovskite thin-film solar cells that achieved a maximum efficiency of 20.83%. Using an additive, and experimenting to find the optimal concentration, the group demonstrated improved control over the crystallization process – crucial for developing stable, repeatable processing.

23.8% efficient tandem cells via slot-die coating

Scientists in Saudi Arabia demonstrated a slot-die coating process for production of perovskite solar cells from a specially engineered ‘ink’. Using the process, the group fabricated a perovskite/silicon tandem cell that recorded 23.8% efficiency.