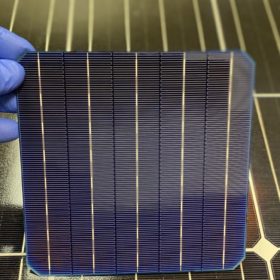

New PV cell architecture creates resistively bounded subcells

Solar Inventions, the winners of the first American-Made Solar Prize, plan to commercialize their newest product, which is claimed to reduce silver content and increase module power, while potentially saving manufacturers up to $1 million per year.

Silver price rally won’t affect PV industry

Silver prices reached their highest levels this week since 2016. But Michael DiRienzo, executive director of The Silver Institute, says prices are still not high enough to complicate silver supplies for the PV industry.

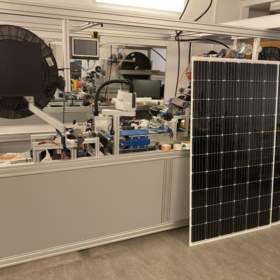

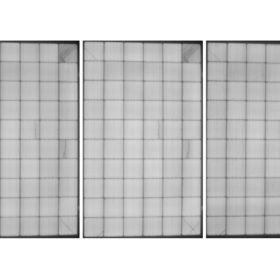

Sticking together

A cell interconnection method developed by a Swedish company promises lower-cost and higher-throughput production of PERC and more advanced silicon PV modules. The process is ready to move to pilot production, and its creators want to play a role in the anticipated European solar manufacturing renaissance.

New metallization paste range from Heraeus

The SOL 7 series comprises five products for Perc, Topcon and heterojunction devices.

Silver demand for PV manufacturing may have peaked in 2019

A Silver Institute study says demand for the precious metal for solar manufacturing accounted for 11% of global consumption last year but reduced solar generation capacity up to 2023 will eat into that figure and ‘thrifting’ technological advances will kick in after that point.

Silver prices expected to drop 3% in 2020

According to the 2020 World Silver Survey 2020 by the U.S.-based Silver Institute, the metal’s price will decline by only 3% this year, despite the impact that the Covid-19 crisis will also have on demand. In the global PV industry, silver demand is forecast to drop 3% from 98.7 million ounces in 2019 to 96.1 million ounces this year.

The raw materials needed for the European Green Deal

A team tasked by the European Commission with estimating the raw material requirements of the European energy transition found if global PV roll-out is high, and the component requirements of certain solar technologies don’t improve by a greater margin, some elements could end up in short supply.

New kesterite solar cell with 8.7% efficiency

Estonian researchers have developed a new monograin powder technology made of microcrystals, which can form parallel connected miniature solar cells in a large module. By replacing copper with silver in the absorber material, the researchers were able to increase the efficiency of the cells by more than 2%.

New metallization tech to reduce microcracks in solar cells

A U.S. research group has developed a metal-carbon-nanotube composite – MetZilla – which can be embedded in commercial, screen-printable silver pastes and is said to reduce the formation of hotspots in solar modules and to prolong panel lifespan. The composite metal contacts are also ‘self-healing’ as they are able to regain electrical continuity after cycles of complete electrical failure caused by extreme strain.

UK researchers warn of potentially rising silver costs

A study has highlighted that the two growth phases of solar panel manufacturing – after the 2008 global downturn and again after 2011 – coincided with higher prices for the precious metal.