The weekend read: Cloud looms over PV’s silver lining

Should heterojunction solar technologies be temporarily shelved? Could copper plating replace screen-printed silver conductive surfaces in cells? Why are tandem cells a likely successor to PERC? Brett Hallam recently sat down with Natalie Filatoff in Sydney to explain the findings of a new study by UNSW that sought to answer these controversial questions.

Novel solar cell architecture to reduce silver costs, improve voltage

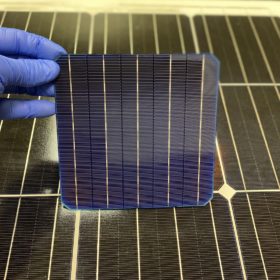

Developed by a U.S.-based start-up, the new manufacturing process is claimed to reduce silver consumption and improve solar module performance by up to 3 W. It consists of connecting sub-cells in series within a single cell in order to increase the device voltage and without requiring cells to be physically broken and rewired.

Scaling up perovskite-silicon tandem solar cell performance

Scientists in Germany investigated various routes to optimizing cell design for perovskite-silicon tandem products. Beyond the perovskite layer itself, they note several other areas that should be optimized for tandem cells, taking silicon heterojunction processing as a starting point. The research identifies several routes to cut costs in cell production, including a significant reduction in indium consumption.

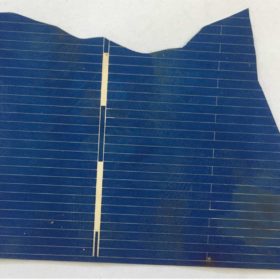

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

Module and shipping cost inflation could cost the world 50 GW of solar next year

The input costs of the two biggest contributors to solar plant development expense have gone through the roof since the world began to come out of Covid-19 lockdowns, to leave project developers with some difficult choices.

New process to recycle silicon, silver and glass from end-of-life PV panels

A €4.8 million EU-funded research project is aiming to develop a process that allows recovering all components of a photovoltaic module.

ITRPV: Large formats are here to stay

The 2021 edition of the International Technology Roadmap for Photovoltaics (ITRPV) was published today by German engineering association VDMA. The report, which forecasts technology trends across the solar industry, expects PERC to maintain its position as the dominant cell technology and notes that large wafer formats are here to stay.

Average silver price expected to reach $27.3 per ounce this year

According to the Silver Institute, global industrial silver production is expected to grow 8% this year due to strong demand for consumer electronics and solar. The price for silver is expected to peak at $32 per ounce later this year and its average price to increase 33% over 2020.

Simulating PV’s silver future

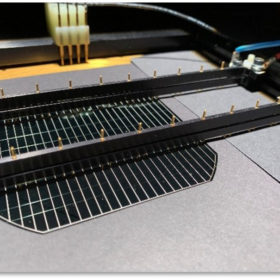

Scientists at Germany’s Fraunhofer ISE developed a model to simulate different setups for screen printing in solar cell metallization. The model provides a comparable ‘screen utility index’ value that can predict the usefulness of different architectures in the printing equipment in relation to the properties of a given silver paste. The approach, says Fraunhofer, will assist the PV industry in reducing the amounts of silver needed in silicon cell manufacturing.

Silver accounts for 10% of PV module costs

The share of silver in the total cost of PV modules has increased by around 5% in recent months, according to US analyst Matthew Watson. He told pv magazine that silver prices are set to rise, adding that the metal will eventually account for an even larger percentage of overall module costs.