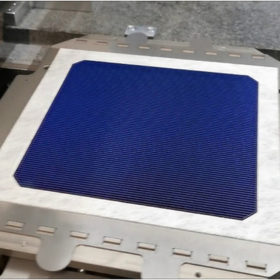

Heterojunction solar cells with lower silver consumption via rotary screen printing

Scientists from the Fraunhofer ISE built a bifacial heterojunction solar cell with a power conversion efficiency of 21.7% via rotary screen printing. They used a machine that is able to achieve a cycle time of just 0.6 seconds per solar cell and enables a strong reduction in silver use.

Silver prices rose 22% in 2021, but slight decrease expected this year

The US-based Silver Institute’s “World Silver Survey 2022” report shows that the price of the metal will fall slightly this year, despite the global economic impact of the war in Ukraine.

Chinese PV Industry Brief: Jolywood, Jinko expand polysilicon capacity

In other news, Canadian Solar revealed it shipped 14.5 GW of solar modules in 2021 and China Power said it installed 1.22 GW more solar generation capacity last year.

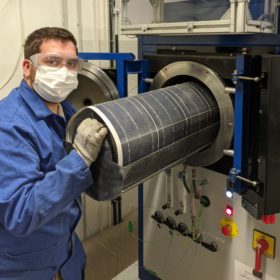

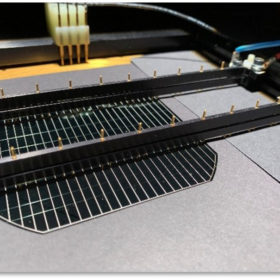

Demonstrator machine for high-throughput solar cell metallization

Developed by Germany’s Fraunhofer Institute for Solar Energy Systems ISE and ASYS Automatisierungssysteme GmbH, the new machine is claimed to increase the print process throughput by a factor of 1.5.

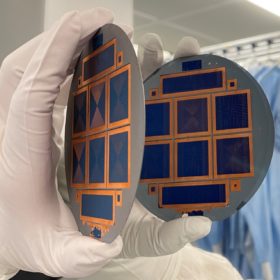

Copper-plated heterojunction solar cell with 22.1% efficiency, 0.99 bifaciality factor

Built by a Dutch-Chinese research team, the cell is relying on a new type of hybrid-shaped Cu finger consisting of a rectangular bottom part and a round top part, which was integrated into the cell through a 2-step electrochemical deposition process. The Cu-plated device outperformed both optically and electrically a reference cell fabricated via screen printing.

New PV module recycling tech from France

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.

Average silver price expected to drop 1% to $24.80 per ounce this year

According to the Silver Institute, global industrial silver demand is expected to grow 8% this year due to strong demand in all key sectors, including the PV industry.

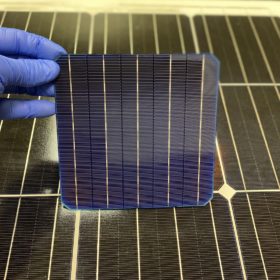

The weekend read: Cloud looms over PV’s silver lining

Should heterojunction solar technologies be temporarily shelved? Could copper plating replace screen-printed silver conductive surfaces in cells? Why are tandem cells a likely successor to PERC? Brett Hallam recently sat down with Natalie Filatoff in Sydney to explain the findings of a new study by UNSW that sought to answer these controversial questions.

Novel solar cell architecture to reduce silver costs, improve voltage

Developed by a U.S.-based start-up, the new manufacturing process is claimed to reduce silver consumption and improve solar module performance by up to 3 W. It consists of connecting sub-cells in series within a single cell in order to increase the device voltage and without requiring cells to be physically broken and rewired.

Scaling up perovskite-silicon tandem solar cell performance

Scientists in Germany investigated various routes to optimizing cell design for perovskite-silicon tandem products. Beyond the perovskite layer itself, they note several other areas that should be optimized for tandem cells, taking silicon heterojunction processing as a starting point. The research identifies several routes to cut costs in cell production, including a significant reduction in indium consumption.