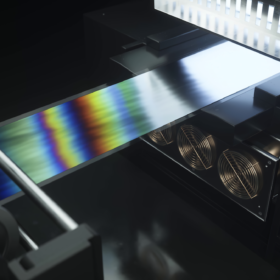

Using digital twin, roll-to-roll platform to design high-performance organic PV devices

An international team of researchers have demonstrated how to speed up the research and development of scalable, high-performing organic solar cells by using an automated, high-throughput platform. It relies on digital twin technology and roll-to-roll (R2R) printing in a closed-loop system.

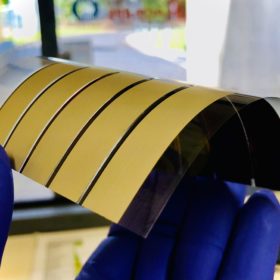

Flexible, roll-to-roll printed perovskite solar cell hits 16.7% efficiency

Australian scientists have demonstrated a flexible perovskite solar cell using roll-to-roll compatible “printing” type processes, which could potentially be applied in large-scale manufacturing. Of particular note is the development of a viable roll-to-roll process to deposit the electrode layer, which has thus far been a major challenge. Cells fabricated by the group achieved a maximum efficiency of 16.7%.

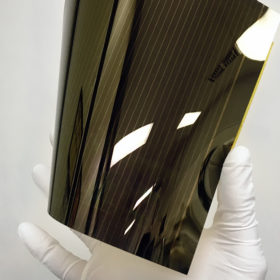

New flexible solar module factory begins operations in the UK

Operated by UK start-up Power Roll, the pilot factory will reach a capacity of 30 MW by year end. The manufacturer uses low-cost roll-to-roll manufacturing processes and patented microgroove patterns to produce flexible solar panels intended for applications on warehouses and agricultural sheds whose roofs are not strong enough for conventional arrays as well as in vehicle-integrated photovoltaics.

Solliance hits new perovskite milestone

European research group Solliance has announced new conversion efficiencies of 13.5% (cell) and 12.2% (module) for its perovskite based PV technology. The group states that the records were achieved in a factory setting, using an industrially scalable roll to roll process.