High-energy, membrane-free organic redox flow battery

US researchers have developed a new high-voltage, membrane-free, nonaqueous lithium-based organic redox flow battery. They say that the elimination of the membrane decreases the upfront costs of the battery by as much as 30%.

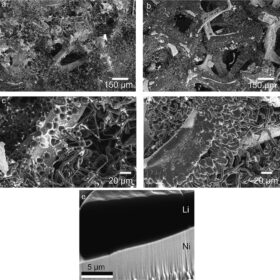

Anode-less redox flow batteries capable of fast cycling

Researchers in the US have demonstrated that replacing the planar lithium anode in a redox mediated lithium-sulfur redox flow battery with a high surface area scaffold enables 10 times faster cycling, up to 10 mA cm−2, without short circuit or voltage instability.

VoltStorage unveils vanadium redox flow battery for commercial use

Germany’s VoltStorage says its containerized 50 kWh vanadium redox flow battery solution can be scaled up to 500 kWh.

Unexpected element improves flow battery capacity, claim US researchers

Researchers at the Pacific Northwest National Laboratory (PNNL) have demonstrated the use of sugar water to improve the performance of flow batteries for grid-scale energy storage.

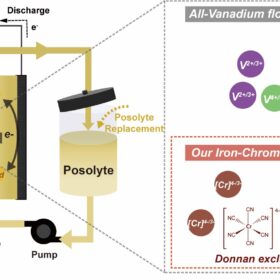

Iron-chromium redox flow battery with high energy density

Researchers led by Korea’s UNIST developed a new redox flow battery concept that utilizes iron and chromium ore for redox chemistry. The proposed battery configuration may reportedly achieve a stable lifetime of 500 cycles, and a high-energy density of 38.6 Wh L−1.

Sumitomo reveals testing results of redox flow battery project in California

Sumitomo says that its 2MW/8MWh vanadium redox flow battery achieved a 99% operating rate at San Diego Gas & Electric’s (SDG&E) facility in California. The battery is expected to retain a capacity rate of 90% or more for 20 years in the electricity market.

Redflow to build 20 MWh redox-flow battery in California

Redflow, an Australian redox-flow battery manufacturer, will build one of the world’s largest zinc-based battery energy storage systems in the United States, after signing a multi-million-dollar deal with the California Energy Commission.

Redflow comissions 30 kWh zinc-bromine flow battery project in Australia

Queensland-based flow battery company, Redflow, has commissioned a 30 kWh zinc-bromine flow battery for the Brisbane City Council.

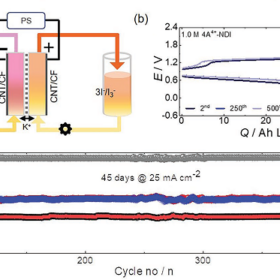

Aqueous redox flow battery based on naphthalene diimide achieves high capacity retention

Scientists in South Korea have developed a highly soluble, stable organic redox-active molecule for use in aqueous redox flow batteries. The newly developed naphthalene diimide (NDI) molecule offered higher storage capacity than existing vanadium devices.

Overcoming thermal issues of vanadium redox flow batteries

Chinese scientists have analyzed reports of thermal issues with vanadium redox flow batteries (VRFB) and existing thermal management methods. They say the operating temperature should be maintained in the range of 10 C to 40 C to ensure VRFBs with high efficiency, weak side reactions, high electrolyte stability, and low crossover.