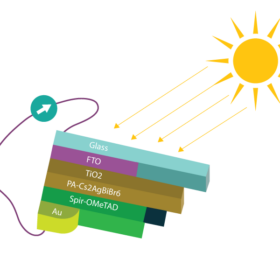

New doping strategy increases lead-free perovskite solar cell efficiency

An international research group has developed a solar cell based on a lead-free perovskite material known as Cs2AgBiBr6. The cell’s absorber was doped with trans-polyacetylene, which reportedly helped the device to improve its efficiency by more than 20%.

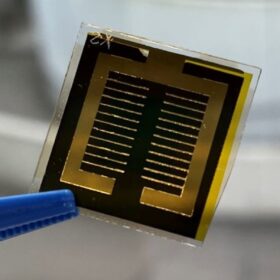

KIT researchers develop18.2%-efficient perovskite solar cell via scalable inkjet process

Researchers at Karlsruhe Institute of Technology (KIT) have developed a scalable two-step evaporation and inkjet process for perovskite thin-film solar cells. The new technique reportedly enables to build champion cells with the same efficiencies as those made with the spin coating process.

Improving perovskite solar cell performance with conductive adhesive ink

Conceived by researchers from Iran, the new conductive adhesive ink is made of polymethyl methacrylate (PMMA) and is used as an interlayer between the cell’s hole transport layer and carbon foil. It reportedly ensures higher cell stability while also providing remarkable efficiency.

Tin halide perovskite solar cell based on new precursor additive achieves 12.22% efficiency

An international research team has developed a new type of perovskite solar cell by using 4-phenyl thiosemicarbazide (4PTSC) as a precursor additive. The device showed an improved open-circuit voltage and “exceptional” long-term stability.

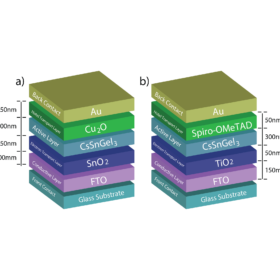

Researchers design tin-germanium-based perovskite solar cell with potential efficiency of 31.49%

Researchers in Malaysia have simulated a mixed cation perovskite solar cell integrating tin and germanium in the absorber. By modulating the perovksite layer thickness, they were able to achieve an efficiency ranging from 24.25 % to 31.49 %

ZSW, First Solar partner to collaborate on thin-film PV

Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW) and First Solar have agreed to work together to develop thin-film PV technologies on a gigawatt scale.

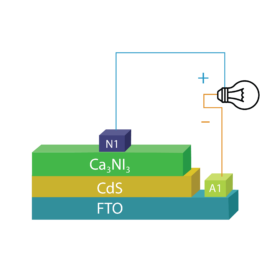

Researchers design 31%-efficient perovskite solar cell based on calcium nitrogen iodide

An international team has demonstrated a perovskite solar cell relying on inorganic calcium nitrogen iodide (Ca3NI3) perovskite and has found this absorber material offers advantages such as tunable bandgap and resistance to heat. The device achieved a fill factor of 81.68%.

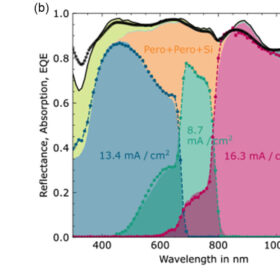

Perovskite-perovskite-silicon triple-junction solar cells have technical potential to reach 44.3% efficiency

A German research team has investigated the optical properties of perovskite/perovskite/silicon triple-junction cells and has found these devices may have a practical efficiency potential of 44.3% assuming idealized electrical parameters. These cells may also potentially achieve a fill factor of 90.1%.

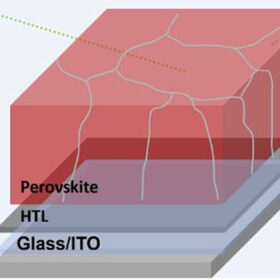

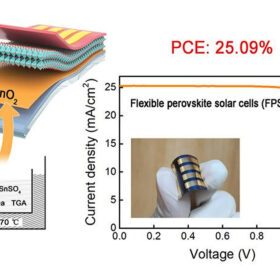

Flexible perovksite solar cell with tin oxide electron transport layer achieves 25.09% efficiency

Researchers in China have developed a new chemical bath deposition technique to deposit tin oxide on a perovskite cell’s flexible substrate without requiring a strong acid. The resulting cell has achieved a certified efficiency of 24.90% and remarkable stability.

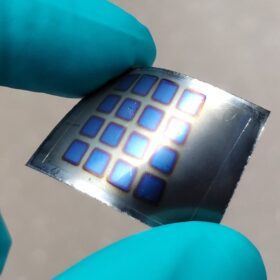

Perovskite-CIGS tandem solar cell based on fexible steel substrate achieves record-breaking efficiency of 18.1%

Scientists in Australia claim to have achieved the highest efficiency ever reported to date for a perovskite-CIGS tandem solar cell built on a flexible steel substrate. In the proposed cell configuration, steel can act as both a substrate and an electrode.