Fine-tuning plasmonic solar cells

Two different studies published this week show new advances in the use of plasmonic enhancement to improve performance and stability of perovskite solar cells.

Flexible, 22.6%-efficient perovskite cells for indoor use

The developers of a perovskite device designed for use under illumination of 100-500 lux say it could be manufactured for $78-108 per square meter.

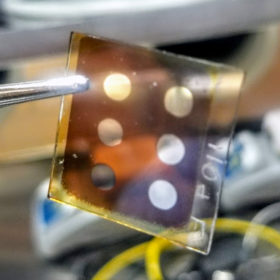

A flexible perovskite solar cell with 11.8% efficiency

U.S. researchers have created an inorganic mixed halide perovskite solar cell which they claim shows no thermal degradation even at 200 degrees Celsius for three days. The device can be used in tandem junction cells and is designed for use in real-life environments with high solar irradiation.

A perovskite electrode to improve hydrogen production

The material was used by scientists in the U.S. in electrochemical cells which use electricity to separate steam into hydrogen and oxygen. The researchers say the oxide of perovskite used in the electrode improves cell performance and reduces operating temperatures.

The week in perovskites

As a focus of research at leading institutes the world over, new developments in the perovskite field come thick and fast almost every week. From x-ray observations on a nanoscale to financing and plans for mass production, pv magazine is bringing together some of the most exciting developments of recent weeks.

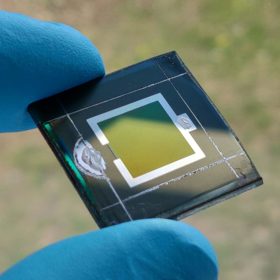

New manufacturing technique for 26%-efficient tandem perovskite solar cell

U.S. scientists have demonstrated a perovskite-silicon tandem cell they claim has low reflectance losses and strong potential for commercial production. The tandem architecture involves a manufacturing process featuring the solution-based blading of perovskites onto textured silicon wafers.

HZB scientists announce 24.16% efficiency for tandem CIGS solar cell

The Fraunhofer Institute for Solar Energy Systems’ (ISE) CalLab has confirmed the new efficiency rating. The researchers have combined semiconductors, perovskites and CIGS to produce a monolithic two-terminal tandem cell.

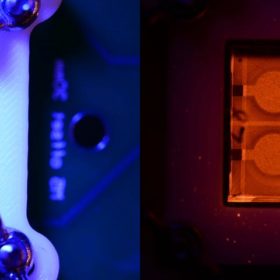

Shine! You’re on photoluminescence camera!

Researchers in Australia and China used intensity-modulated photoluminescence to map the series resistance of perovskite solar cells with a technique which could further understanding of the causes of instability issues in such devices.

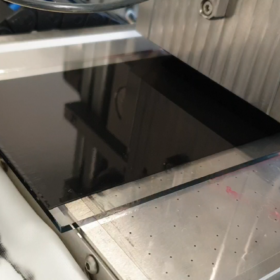

Swiss researchers unveil new perovskite process

A group of scientists at Switzerland’s Federal Laboratories for Materials Science and Technology (EMPA) has demonstrated a new manufacturing process, based on slot die coating, for the production of perovskite thin-film solar cells. The laboratory has fabricated small perovskite modules using this process and has plans to move into the field-testing phase later this year.

New technique to improve titanium dioxide films in dye‐sensitized solar cells

Dutch scientists are producing mesoporous titanium dioxide thin films at room temperature by using the papain enzyme in a dip‐coating procedure. This fully organic process could facilitate the development of cheaper, more efficient dye‐sensitized solar cells.