Perovskite solar cell based on metal-organic framework with 22.02% efficiency

Scientists in Hong Kong have developed a cell they say retains more than 90% of its initial efficiency under accelerated testing conditions. The device is based on two-dimensional metal-organic frameworks.

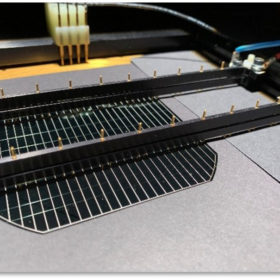

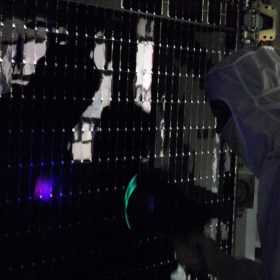

Modular systems to produce perovskite-silicon cells on six-inch wafers

Researchers in Germany are scaling up efforts to bring perovskite-silicon tandem solar cell technology into industrial scale production. The scientists say manufacturing cells of that kind is possible on widely-available six-inch silicon wafers and modular systems are being designed to do so at scale.

German-led consortium aims for 33% efficient perovskite-silicon solar cell

The Institute for Solar Energy Research Hamelin (ISFH), the Karlsruhe Institute of Technology (KIT) and the Institute for Materials and Components in Electronics at the University of Hannover, as well as Centrotherm, Singulus, Meyer Burger and Von Ardenne are involved in a research project aimed at achieving a 27% conversion efficiency for silicon solar cells based on perovskite.

Perovskite structure also benefits batteries

Scientists at Germany’s Karlsruher Institute of Technology are leading an investigation into a new lithium-ion battery anode. The innovation has a perovskite crystalline structure and, according to the researchers, could provide strong all-round performance from simpler, cheaper production methods than those used for other anode materials.

Tandem solar modules vs commercial crystalline

Researchers in France have tried to predict the competitiveness of tandem PV modules against commercial crystalline products in 2030. Crystalline products will be 22-24% efficient in a decade, according to the researchers, possibly 25% if interdigitated back-contact heterojunction versions become mainstream. To compete, tandem devices will need to offer similar life spans and degradation rates, plus efficiencies of 30%.

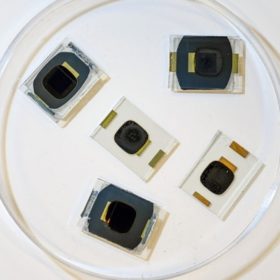

Rooftop solar window based on semi-transparent perovskite solar cells

A prototype of an energy-harvesting, solar-powered smart window device has been developed by scientists from the U.S. Department of Energy’s Argonne National Laboratory. The window was created by integrating a semi-transparent perovskite solar cell and a multi-layer nanophotonic coating.

Scientists in China give flexible perovskites a backbone

A team of researchers led by Nanchang University in China trialed a polymer based hole transport layer to flexible perovskite solar cells, using a glue to attach it to the active perovskite. The team was able to assemble the 19.87%-efficient cells into a small flexible module suitable for wearable solar applications, and says its design was inspired by the structure and movements of human vertebrae.

An 18.12%-efficient perovskite solar cell with reduced hysteresis

Researchers in Japan have modified the tin(IV) oxide layer of a perovskite device with a fullerene-derivative-based self-assembled monolayer to produce a cell they claim offers stability and a reduction in the hysteresis effect which makes predicting power output so tricky.

Australian scientists claim breakthrough in perovskite stability

In a world-first, perovskite solar cells developed by Australian scientists have passed a series of heat and humidity tests using a low-cost solution to overcome some of the challenges that are hindering the technology’s commercialization. The scientists did this by suppressing the decomposition of the perovskite cells using a simple, low-cost polymer-glass blanket.

A pressure-assisted technique to increase perovskite solar cell efficiency

Researchers in the United States claim to have significantly increased the efficiency of a perovskite solar cell by applying a range of pressures to the device. According to them, pressure-assisted processes such as lamination, cold welding and rolling/roll-to-roll processing can be used to improve interfacial surface contacts in perovskite cells.