Perovskite solar module with 17% efficiency

A research team led by the University of Rome Tor Vergata in Italy has fabricated a perovskite solar module with a total active area of 42.8 cm2 and aperture area of 50 cm2. The panel was built with 20%-efficient perovskite cells connected in 14 series and was able to retain 90% of the initial efficiency after 800 h of thermal stress at 85° C.

Polyelectrolyte-based inverted perovskite solar cell with 20.29% efficiency

Taiwanese researchers have added bathocuproine (BCP) molecules to three different kinds of solvents used in perovskite cells and have ascertained how this combination increases the carrier mobility and passivates the electron-poor defects. Furthermore, they utilized a polyelectrolyte (P3CT-Na) thin film as hole transporting material instead of commonly-used thin films based on PEDOT:PSS.

URE Corp wants to begin TopCon solar cell production this year

The Taiwanese cell and module manufacturer claims to have achieved a 23.5% efficiency for its TopCon solar cell.

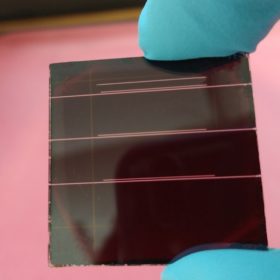

Flexible perovskite quantum dot solar cell with 15.1% efficiency

An international research team has developed a PV cell with all-inorganic cesium-lead iodide (CsPbI3) perovskite. The scientists added phenyl-C61-butyric acid methyl ester (PCBM), one of the best electron acceptors in organic PV cells, into the CsPbI3 quantum dot layer.

Air-processed perovskite solar cell with 18.3% efficiency

The methylammonium-free perovskite solar cell was fabricated through a deposition technique that is claimed to reduce by around 30% the use of solvents during the perovskite deposition. The estimated overall cost of the proposed synthetic process is around €0.025 per cell.

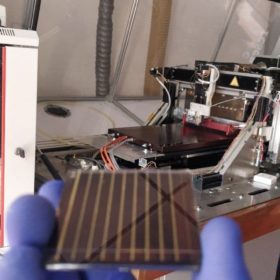

Inverted blade-coated perovskite cell with 23.2% efficiency

A US research team has improved the efficiency of a blade-coated perovskite cell with a p-i-n structure by reducing iodine-induced charge traps in the films. They used the cells to fabricate a mini module with an efficiency of 18.2%.

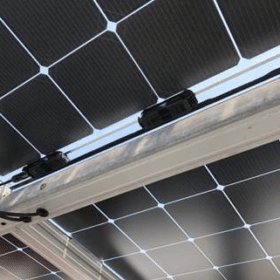

Laser-based P3 scribing for perovskite mini modules with 19% efficiency

German scientists have improved the scribing method to interconnect perovskite PV cells, in order to then upscale them into mini PV modules. They established suitable laser fluence ranges for nanosecond and picosecond lasers and found that the former results in higher efficiency levels.

Metal-perovskite-metal back contact solar cell with 4.31% efficiency

A numerical study by researchers at India’s Chitkara University has shown enhanced charge extraction in metal-perovskite-metal back-contact solar cell structure through electrostatic doping. The proposed design yielded a 59.4% improvement in power conversion efficiency over previously reported structures.

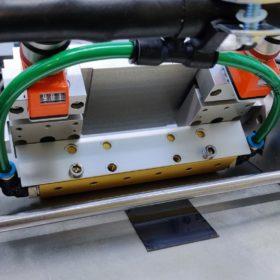

Mini perovskite solar module with 18% efficiency from CEA-INES

The mini panel has a surface of 10 cm². It was built with a manufacturing technique that is claimed to be compatible with the integration of perovskite into heterojunction silicon solar cells in tandem architecture.

MIT scientists develop perovskite solar cell with 25.2% efficiency

The US researchers claim to have achieved the remarkable result by adding a special conductive layer of tin dioxide bonded between the conductive layer and the perovskite material. They also improved the perovskite layer special additives that do not alter the material’s bandgap.