European team targets 20%-efficient perovskite modules using industrial processes

The LUMINOSITY project consortium aims to develop 20%-efficient metal halide perovskite prototype modules measuring over 900 cm², designed for a 20-year lifespan and compatibility with roll-to-roll (R2R) processing.

Perovskite solar cell built with slot die coating achieves 19.17% efficiency

A team from Jeonbuk National University in South Korea used slot die coating (SDC) to produce uniform high-quality perovskite films, which they used in a perovskite solar cell that achieved 19.17% efficiency and lab cell-sized modules that achieved 17.42% efficiency.

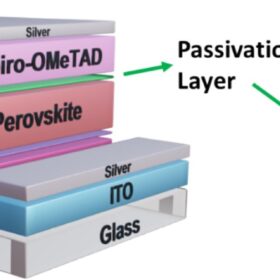

New passivation strategy increases efficiency of chloride-iodide-based perovskite solar cells by 15%

Although local defects in chloride-iodide-based perovskite are hard to avoid due to ion migration, a group of scientists have now found a way to passivate them. They used different combinations of 4-chlorobenzylammonium chloride and 4-chlorobenzylammonium bromide beneath the hole transport layer and reached up to 15% improvement in efficiency.

New cleaning tool for perovskite, organic PV roll-to-roll production equipment

A German research team has developed a precise cleaning process for electrode deburring in perovskite and organic solar PV roll-to-roll production lines. It is based on commercially available equipment from Germany-based Acp Systems.

Perovskite solar cell achieves higher stability with new tin oxide layer

Using atomic layer deposition, a research team from the City University of Hong Kong has created an an oxygen-deficient tin oxide layer to replace the more common fullerene electron transport layer in perovskite solar cells. The result is a 25%-efficient device that is able to retain around 95% of its efficiency after 2,000 h.

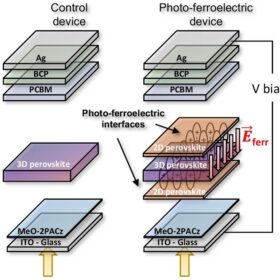

Solar cell based on ferroelectric 2D/3D/2D perovskite junction achieves 24% efficiency

The experimental device achieved an open-circuit voltage of 1.21 V, which is the highest value reported to date for highly efficient perovskite photovoltaics. The cell is based on a photo-ferroelectric 2D/3D/2D perovskite junction integrating a 2D ferroelectric perovskite single crystals in the perovskite bulk.

Perovskite solar module achieves 21.44% efficiency via new passivation tech

Researchers have developed a novel passivation process for formamidinium lead iodide perovskite films, which reportedly resulted in solar cells with 23.69% power conversion efficiency, and modules with 21.44% certified efficiency. After 1000 hours, the hetero-polytypic passivated devices maintained 92% of their initial efficiency, outperforming untreated devices.

Perovskia Solar raises $2.36 million, secures 10 IoT clients

Perovskia Solar has completed a seed funding round and secured 10 Internet of Things (IoT) companies as clients. The company designs custom-made solar cells for devices like keyboards and smartwatches that can generate electricity indoors.

Flexible perovskite solar cell based on polycarbonate substrates achieves 13.0% efficiency

An international research group demonstrated the first perovskite solar cells on polycarbonate substrates, suitable for flexible PV applications. Using an industrially compatible fabrication method, the group produced devices with 13.0% power conversion efficiency, 87% of which was maintained after 1000 bending cycles at a radius of 20 mm.

Italian scientists build 12.6%-efficient nickel oxide-based large-area perovskite solar modules

An Italian research group has fabricated 110 cm² perovskite solar module with an inverted configuration and a hole transport layer that uses nickel oxide instead of commonly utilized poly(triarylamine) (PTAA). The proposed architecture aims to achieve high efficiency that is competitive with PTAA-based panels while improving stability.