‘Nobody is making money right now’

As part of our Intersolar 2024 interview series, pv magazine spoke with Bill Mulligan, CEO of Singapore-based IBC solar module maker Maxeon. He states the IBC technology will remain competitive despite overcapacity and dropping modules prices and says Maxeon may enforce intellectual property rights with all existing and new back contact competitors that are allegedly utilizing its technologies.

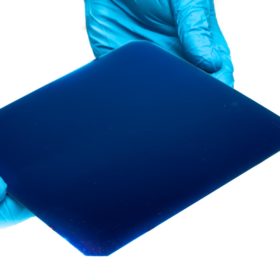

IBC solar cell based on ultrathin black silicon wafer achieves 16.4% efficiency

A Spanish-Finnish research team has fabricated an IBC solar cell with an ultrathin black silicon wafer with a thickness of 40 µm. The device is based on vanadium oxide and laser-processed phosphorus-doped silicon carbide stacks as hole and electron transport layers, respectively.

Video: ISC Konstanz director predicts 50% global market share for IBC solar panels by 2030

Radovan Kopecek, the co-founder and director of Germany’s ISC Konstanz, says interdigitated back contact (IBC) tech could account for half of the global market for solar modules by 2030. He says IBC will start to dominate once TopCON and HJT get stuck at certain efficiency limits, and he believes TOPCon will be the first victim.

IBC solar modules may drive TOPCon out of market by 2028, says tech expert

Radovan Kopecek, an expert on interdigitated back-contacted (IBC) tech, says that IBC solar panels could capture more than 50% of the global market by 2030, potentially pushing TOPCon products out of competition. He told pv magazine how this transition might materialize and discussed the tech advancements that could make it possible.

Novel IBC solar cell architecture based on crystal photonics shows efficiency potential of 29.1%

Scientists in Germany designed a poly-Si on oxide (POLO) interdigitated back-contact (IBC) solar cell integrating photon crystals and found this architecture has the potential to reach a power conversion efficiency of over 28%, which would be 1% higher than the current practical limit set by the scientific community. They also found that by improving passivation, the efficiency may be raised up to 29.1%.

Four-terminal III-V solar cell with 32.57% efficiency

Scientists at the US National Renewable Energy Laboratory have simulated a III-V solar cell by stacking gallium arsenide films onto interdigitated back contact silicon solar cells with a glass interlayer. The scientists have already done some initial mini-module integration work, but significant size scaling will ultimately be needed to reach commercialization. The cell currently has an active area of 1 cm2.

3-D multi‐ribbon interconnection tech for IBC cells

The interconnection tech, developed by scientists at the Belgian research institute Imec, is based on a three-dimensional fabric of encapsulant with incorporated horizontal and vertical solder‐coated metal ribbons. Mini solar modules built with the proposed technique have provided interesting results in tests for thermal cycling reliability, showing very limited degradation.

Finnish solar manufacturer finally starts production in Vilnius

Valoe completed the 15-month purchase process of a 60 MW cell production line from Solitek in the spring and installed interdigitated back-contact production equipment. It hopes to begin deliveries in the next quarter.

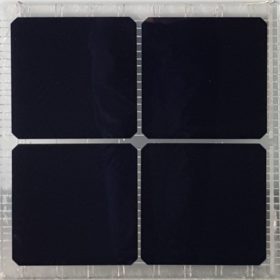

Zebra IBC cell with 24% efficiency moves to large-scale production

Netherlands based manufacturer Energyra this week introduced a new back contact module, which it has developed in partnership with Dutch research institute TNO and Germany’s ISC Konstanz. A prototype module was unveiled yesterday in a small presentation at Energyra’s factory in Zaandam, Netherlands. The company is targeting large-scale manufacturing by the end of 2020.

CIGS solar cell with IBC structure and up to 19.7% efficiency

Scientists in the Netherlands have demonstrated an interdigitated back contact copper-indium-gallium-selenide solar cell with a sub-micron thickness of 673nm. The device has an aluminum oxide and magnesium fluoride-based anti-reflective coating.