Using deep eutectic solvents to separate EVA films from end-of-life PV modules

A Chinese-Australian research team has used for the first time deep eutectic solvents for separating EVA films for end-of-life PV panels. The result is reportedly a 100% separation rate accompanied by an aluminum removal efficiency of 98.4%

Scientists unveil desert solar modules with higher performance ratio, reduced temperature sensitivity

Researchers in Morocco have carefully configured and tested a novel desert solar module optimized for harsh desert climates. The new design delivered a 5.8% improvement in performance ratio, a 1.95% increase in efficiency, and reduced temperature sensitivity by 0.85% compared to standard modules.

Are the days of cheap finance for Chinese solar over?

The Chinese PV industry has benefited from the availability of substantial finance over the past two decades, supporting the development of the renewable, zero-carbon capability essential for meeting the goals of the Paris climate agreement. Easy access to finance has led to unsustainably low prices and unnecessary losses, however, impacting China’s ability to sustain support for renewable energy systems. As the nation expands clean power installations and enhances grid-balancing capacity, maintaining consistent financial support has become more challenging.

In search of the perfect polymer for PV backsheets, encapsulants

Scientists in Austria have examined the impact of different backsheet and encapsulant material combinations on module performance and degradation. This led them to develop a model to quantify the degradation rates of different materials, potentially helping manufacturers to identify better, longer-lasting materials for these vital module components.

Hanwha Solutions to set up TOPCon module production line, build EVA factory

Hanwha Solutions has unveiled a $548.8 million plan to enter the TOPCon module business and expand its EVA production capacity in South Korea.

Quanex releases new solar panel sealant

Texas-based Quanex’s new sealant helps to delay power losses over a PV module’s lifetime and extends useful lifetimes by locking out moisture.

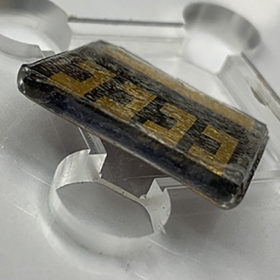

EVA the next supply chain pinch point for solar

With polysilicon production capacity having been rapidly rolled out after last year’s shortages, China analyst Frank Haugwitz has suggested global manufacturing capability for the ethylene vinyl acetate used on PV panels could struggle to keep pace with what is expected to be another record year of demand for solar.

Lead absorbing encapsulant for perovskite solar cells

Scientists in the United States developed what they describe as a ‘scotch-tape like’ solution, which can absorb potential lead leakage from perovskite solar cells, preventing the toxic material from entering the environment. The tape, according to the scientists, can easily be integrated with existing encapsulation strategies, and was shown to absorb 99.9% of lead leaked from cells from that were severely damaged.

China’s emission-reduction action squeezes PV production

Industrial shutdowns and reduced factory production capacity levels indicate the companies producing the raw materials used by solar manufacturers are being afflicted by electricity consumption measures just as other sectors are. It is not clear whether the solar industry will be afforded any favors by Beijing, as analyst Frank Haugwitz explains.

The weekend read: Bifacial drives PV encapsulant switch

Suppliers of encapsulant materials – plastic sheets that are heated to laminate together the components in PV module stacks – are rapidly expanding to keep pace with module manufacturing in Asia and other parts of the world. Ethylene-vinyl acetate (EVA) continues to dominate the market, but new developments in module technology are driving a slow shift to more costly polyolefins.