Only5mins! – Thin-film solar researcher discusses future of CIGS

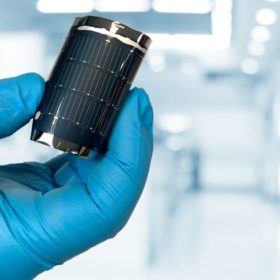

The future outlook for copper indium gallium selenide (CIGS) solar cells is bright, due to recent R&D achievements and efficiency gains, according to Ayodhya Tiwari, head of laboratory at Switzerland’s Federal Laboratories for Materials Science and Technology (EMPA). CIGS has already shown its value in building-integrated PV applications, but as production volumes increase in the years ahead, ground-mount plants and big utility-scale installations could also become feasible, says Tiwari.

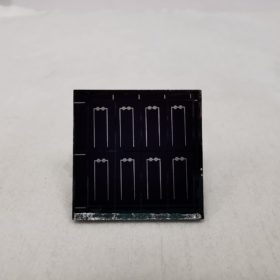

CIGS-perovskite tandem solar module with 21.1% efficiency

German scientists have built a tandem perovskite-CIGS panel measuring 9 square centimeters, with organometallic perovskites for the top module.

Roadmap to achieve CIGS solar modules with efficiencies above 20%

Japanese scientists have described the steps that need to be taken to improve the average efficiency of CIGS solar modules, from around 18.5% at present to more than 20%. They presented all of the critical technical factors that are currently holding the tech back from broader market adoption.

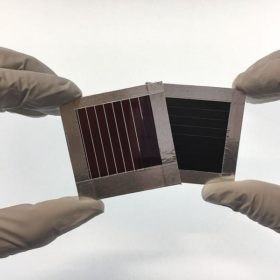

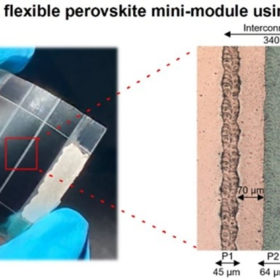

Four-terminal flexible perovskite-CIGS tandem mini-module with 18.4% efficiency

Swiss scientists have built a 4T tandem perovskite/CIGS mini-panel with a geometric fill factor of over 93%. It combines a 10.8%-efficient mini perovskite module and a 15.1%-efficient CIGS device.

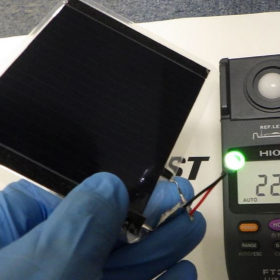

Cutting out cadmium for a 16.7%-efficient flexible thin-film solar cell

Scientists in Japan have developed new processes for CIGS solar cell manufacturing, entirely eliminating the use of cadmium and replacing a waste-intensive wet chemical stage. With a thin film deposited on a flexible steel substrate, the group achieved 16.7% efficiency, which it says is a record for a cell of this type produced using scalable fabrication processes.

Norwegian investor raises stake in company developing ‘perovskite-boosted’ solar cells

Swedish business Evolar is working on a bolt-on piece of production equipment which would upgrade the cell lines of conventional manufacturers with a perovskite lift in performance.

Midsummer begins construction on 50 MW factory in Italy

The factory will be built with the financial support of the Italian government. It will mostly serve southern European markets.

CIGS solar panels for weight-constrained rooftops

U.S. thin-film module manufacturer Sunflare is ramping up production at its factory in China. The company makes four different CIGS modules.

Swiss scientists achieve 21.4% efficiency for flexible CIGS solar cell

The result was confirmed by Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE). The cell was fabricated through a low-temperature co-evaporation method for the growth of the light-absorbing CIGS semiconductor thin film.

Pure sulfide CIGS solar cell with 15.2% efficiency

The device was built by an international research team. The cell features a buffer layer based on zinc sulfide oxide and a low copper absorber. The cell showed an open-circuit voltage of 920 mV. And though a different material from the widely commercialized CIG selenide PV thin films, the researchers claim similar processes could be used in its large-scale manufacturing.