Ultrathin CIGS cell based on tungsten disulfide promises 25.7% efficiency

The novel solar cell uses tungsten sulfide as the back surface field layer. According to its creators, this layer can be included in conventional CIGS solar cells to improve their efficiency and reduce the absorber material’s cost.

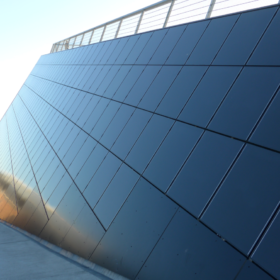

Midsummer builds 200 MW CIGS solar module factory in southeastern Sweden

Swedish thin film solar manufacturer Midsummer has selected a factory in southeastern Sweden to develop its new solar module production facility, which will produce copper indium gallium selenide (CIGS) solar cells for the European market.

First Solar’s unit, Uppsala University present CIGS solar cell with world record efficiency of 23.64%

The new solar cell achieved a maximum power conversion efficiency of 23.75% and a certified efficiency of 23.64%, thus beating the previous world record of 23.35% achieved in 2019 by Japan’s Solar Frontier. The result was confirmed by the Fraunhofer ISE.

Ascent Solar announces 17.55% efficiency for CIGS tech

Ascent Solar, a US-based manufacturer, has achieved an efficiency of 17.55% for its copper, indium, gallium and selenide (CIGS) technology. It says it plans to release a new CIGS solar module with this efficiency rating soon.

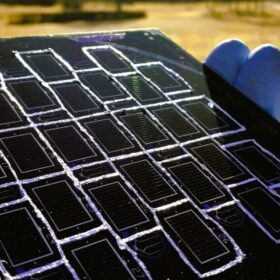

Belgian startup offers custom CIGS solar foils

Enfoil is developing a CIGS thin film custom manufacturing business, targeting building-integrated PV applications, such as powering sensors or track & trace sub-systems in trucks. The company is a spinoff of Hasselt University and imec, the Belgian research institute.

Novel technique to recover 100% of silver from CIGS solar cells

Swedish researchers have developed a method to recycle valuable metals from flexible thin film copper-indium-gallium-diselenide (CIGS) solar cells under mild leaching conditions. They showed that 100% of silver and 85% of indium can be recovered after 24 hours of leaching at room temperature using two moles of nitric acid.

Roadmap to achieve CIGS solar modules with efficiencies above 20%

Japanese scientists have described the steps that need to be taken to improve the average efficiency of CIGS solar modules, from around 18.5% at present to more than 20%. They presented all of the critical technical factors that are currently holding the tech back from broader market adoption.

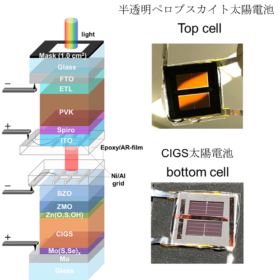

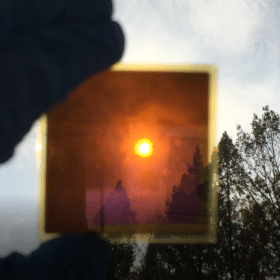

Four-terminal tandem perovskite/CIGS solar cell with 26.2% efficiency

Japanese scientists have developed a tandem device with a 19.5%-efficient perovskite top cell. They claim to have created a semi-transparent perovskite solar cell while maintaining high performance.

Indium supply not an issue for CIGS industry

Scientists Ayodhya Tiwari and Daniel Lincot recently spoke to pv magazine about the future of copper indium gallium selenide solar tech, which could play a key role in providing flexible, lightweight products in the building-integrated PV segment.

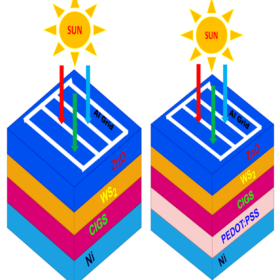

Semitransparent bifacial CIGS cell with 10.5% efficiency

The solar cell was developed by Korean scientists for power-generating window applications. They built the device with transparent conducting oxide (TCO) rear contacts and a textured polydimethylsiloxane (PDMS) layer with light-scattering and antireflection properties.