Meyer Burger secures $255.2 million to scale up production capacity to 3 GW

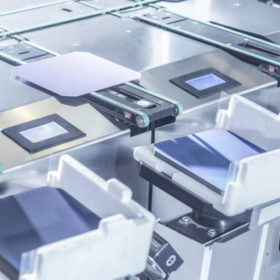

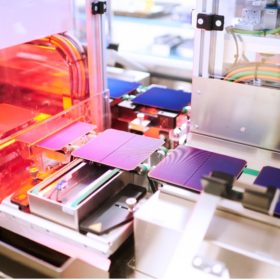

Swiss PV manufacturer Meyer Burger says it wants to rapidly expand its production of heterojunction solar cells and modules, following its recent supply agreement with US project developer DESRI.

Saint-Gobain acquires stakes in Swiss BIPV manufacturer Megasol

Saint-Gobain has acquired a minority stake in Megasol, a Swiss manufacturer of building-integrated photovoltaic (BIPV) modules.

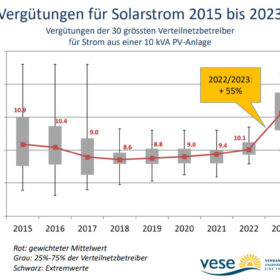

Swiss grid operators to raise surplus solar tariffs by average of 55% in 2023

Switzerland’s grid rates for surplus solar power will increase from an average of CHF 0.101 ($0.10)/kWh to CHF 0.155/kWh in the year ahead, mainly due to rising electricity prices.

Switzerland launches tender to assign free-of-charge areas for PV along highways

The Swiss Federal Roads Office (FEDRO) started yesterday the selection process to assign these areas free of charge to solar developers. Interested developers will have time until February 24 to express their interest in these surfaces.

The Hydrogen Stream: BMW starts in-house production of fuel cells for iX5 Hydrogen

BMW Group said it is targeting the premium segment with its iX5 Hydrogen car, Topsoe revealed that it will invest $267 million to build the world’s largest SOEC electrolyzer plant in Denmark, and Bosch announced plans to invest $200 million in US fuel cell production.

Axpo commissions 2.2 MW vertical alpine PV project on dam

Axpo said its new 2.2 MW system is the largest alpine solar plant in Switzerland. It is expected to supply around 3.3 million kWh of electricity per year, with an above-average electricity yield in the winter months.

Switzerland wants to deploy solar along highways

The Swiss Federal Council has amended the National Roads Ordinance to allow the country to generate renewable energy on free surfaces along major thoroughfares, such as noise barriers and rest areas.

Long-term, heat-based energy storage in aluminum

Nine partners from seven European countries are involved in the €3.6 million ($3.7 million) “Reveal” research project, which says buildings could be heated in the future by storing energy from PV, wind and water in aluminum.

Meyer Burger ramps up solar panel plans

Switzerland’s Meyer Burger is accelerating the expansion of its solar panel production capacity, following the extension of the US solar tax credit for PV manufacturers and an order from developer DE Shaw for 3.75 GW of US-made heterojunction modules.

Meyer Burger secures silicon wafer supplies from Norway

Meyer Burger has announced that it has concluded a binding supply agreement with Norwegian Crystals for silicon wafers to use in heterojunction cell manufacturing. Hydro facilities primarily power the production of the wafers and their precursor materials in Norway. Combined with the shorter distance they’ll have to travel, this adds up to a low carbon footprint.