On Jan 22th, 2020, Trina Solar, a global leading provider of integrated PV modules and smart energy solutions, has its first module product with 210 mm size wafer off the assembly line. Feb 27th, through the internet, Trina officially announced to the world the launch of its milestone module product, the Duomax V bifacial module, and roared the company stepping into a new era with unit power of 500W.

“We have had the consideration of upgrading to bigger size for quite a long time. And the decision we made of choosing 210 mm wafer is because of our strategic thinking, massive discussions with business partners and plenty of scientific experiments” Said by Yin Rongfang, vice general manager and executive vice president of Trina Solar in a telephone interview. “Our R&D team input into the prototype development as early as in August of 2019, and today we finally have it launched.”

As wildly known, the bigger of the wafer size, the more power of the cell and module, and even with better conversion performance. In PV industry, the pursuit of bigger power and better efficiency never stops.

The past variety of wafer size types including from old 125mm to later 156, 158, 161 and even 166mm, actually derived from the development of the semiconductor industry. From the perspective of product spreading, PV silicon wafers lag behind semiconductor wafers by 1-2 generations. The main reason is that the downstream added value of semiconductor industry is very high and can withstand the cost pressure from upstream. But for PV, the downstream chain is extremely cost sensitive and only when the upstream costs decreased, then will it become popular. However, once the cost of the new generation silicon wafer is close to that of previous one, size upgrading will take off due to its comparative advantages.

But why Trina stands for 210 formula, not others?

“When we consider which size is the best choice, firstly we think the size should be unified, not in many types. And also we believe the size naturally relies on equipment capability, not only R&D ability.” Explained by Yin on this matter. “We then have discussed with many of our suppliers, partners, customers and industrial related participants from wafer production, cell technology, logistics, and to system installations, etc. And we found the 210 mm size is the largest but achievable size for future five years, which means no further argument is needed any more for this issue in the next five years and the entire supply chain could be stabilized.”

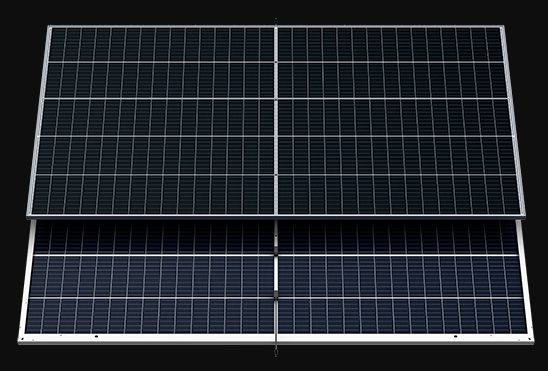

Besides, Trina has taken a series of experiments on module technologies attached to the bigger wafer to make it either compatible to specifications of existed parts, and with maximum of own advantages. The newly launched Duomax V is with as high as over 500 W for single piece, and conversion rate of 21%, which makes it qualified to extreme requirements even like from China’s Super Top-Runner Program.

Besides the wafer size, there are several compelling features of this impressive product too. Trina creatively applied with trisection cut of the cell based on their test which made them believe the best choice compared with half-cut and even quarter or quintile cut. The panel utilized with non-destructive cutting to reduce the hidden cracks and increase the stress resistance. The 9-14 multiple bus bars (MBB) setting maximizes the power output by a plus of 0.4-0.6% and helps both in optical and electrical properties. By high-density packaging with small gaps, the module size of Duomax V is only longer than Trina Solar’s 166mm wafer size module with a distance less than 8 cm, and wider less than 6 cm.

Vice president of Trina Solar, director of the State Key Laboratory of PV Science and Technology, Dr. Feng Zhiqang, concluded the advantages of Duomax V: “The combination of trisection cut and 9-14 MBB technologies can help this panel to achieve higher power, with lower risks of either in processing or hot spots generation. Also it provides high safety for junction box, reduces the chance of hidden cracks, and with no risk of inverter current-limiting power loss. The Duomax V contains the best technical solutions of PV panels with 210 mm wafer size in the next three to five years.”

According to third-party’s calculation based on a real PV plant locates in Heilongjiang province, the shift from 410 W double-glass bifacial module to the new 500 W Duomax V module will generate a significant decline in balance of system (BOS) by 6-8%, and of 3-4% deduction for levelized cost of electricity (LCOE). Considering the better profitability, Duomax V will attract PV investors and end users.

For the technologies applied in Duomax V, Yin stressed the importance of intellectual property protection, he said: “what I want to reiterate is all the main technologies we used like the trisection cut and related MBB, Trina has applied for patents. We welcome all kinds of communications and discussions, but we hope the intellectual property are fully respected.”

According to PV InfoLink, Trina Solar has achieved more than 10 GW of module shipment in 2019 and again ranked No. 3 among all major players. Trina plans that by end of 2021, all new production capacity will be compatible with 210 mm. According to existed orders and production arrangement, Duomax V will start the mass production since Q3 2020 and the total capacity of this year is estimated to reach more than 5 GW. The company has fully prepared for the coming era of PV 5.0, even the outbreak of COVID-19 won’t stop their passion.

When talking with Yin about the affection of this outbreak, he replied with confidence. “Because of previous SARS experience of 2003, we attached great importance to this epidemic. Trina has established an epidemic response team the first time to deal with the issue. So far the affection to us is minimized. While the COVID-19 has disrupted the market to some degree in the short term, we are very confident it can be effectively contained in the future. We expect the global market is not going to swing significantly in 2020. There may be a stable growth of approximately 10-15% from 2019 or higher. Judging from a short-term perspective, the 1st half of this year may witness a drop by an expected 10-20%. Still, judging from the entire year, the postponed demand of the first two quarters will be unleashed in the 3rd quarter, hence we expect quite a small impact on the global market over the whole year.” Yin added, “For Trina Solar, we will set a series launch of our new modules. And Trina Solar looks forward to promoting with a comprehensive solution by integrating our new modules.”

Trina Solar is a real veteran among Chinese PV manufacturers. The company has always been brave in aggressively integrating latest technologies into PV module products. From firstly the promotion of modules in dual-glass double-sided, and MBB technologies to the launch of ultra-high-power modules this time, the company always wear the yellow jersey. This is not only about braveness, but also about R&D capability, quality control, globalized distribution channels, self-confidence, ambition and, vision.