New technologies, new risks: edge ribbon cracking

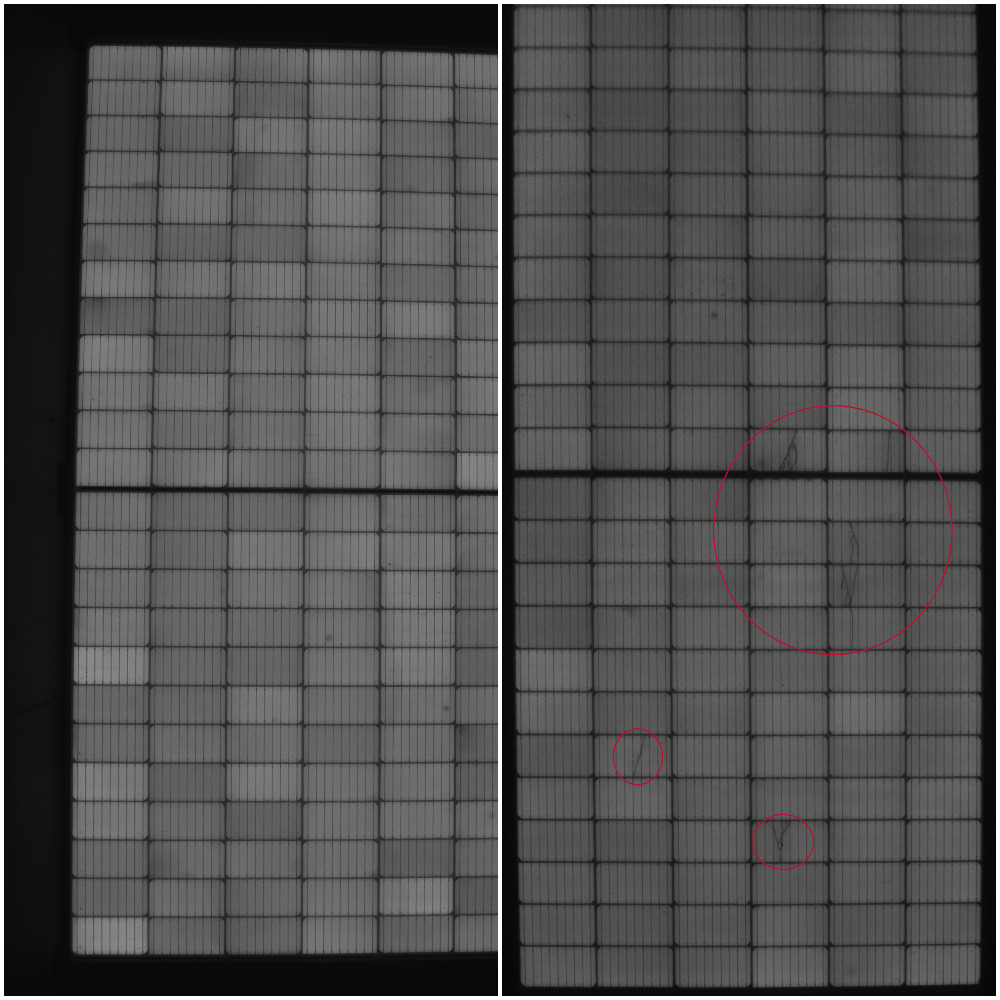

CEA has noted that cell cracks can begin to form at the point where interconnect ribbons cross the edge of the cell, and are initially so small as to be difficult to spot even in EL imaging (left image). Further stress on the cells during handling, installation and operation can cause the small cracks to propagate into more serious, performance-threatening issues.

Images: CEA

Stay informed

pv magazine is the leading trade media platform covering the global solar photovoltaics industry. Log in or purchase a digital or print version of this issue to read this article in full.