Green hydrogen of Africa

Africa’s size and its abundance of renewable energy and mineral resources make it ideal for green hydrogen production. Indeed, some large-scale projects are already in the making. But will green hydrogen become just another exploited African resource? pv magazine recently sat down with Chigozie Nweke-Eze, founder of Integrated Africa Power (IAP), to discuss the green hydrogen opportunity for Africa and whether resources can be used for export industries when domestic needs are so high.

From lead to lithium

The transition to clean energy is well underway, and it is widely accepted that battery-based energy storage has a major part to play. We therefore have a duty to build energy storage that will leave a positive legacy, and this is why a full understanding of the materials we use and how we use them is so important. Keeping informed of the benefits and downsides of different battery chemistries is what will enable us to make the right moves towards building renewable energy infrastructure that will stand the test of time, writes Carlton Cummins, CTO and co-founder of clean tech firm Aceleron.

Integrated giants emerge

The giants of the Chinese PV industry are now integrated along both ends of the supply chain, amid expectations for strong demand and price volatility. Module makers are adding polysilicon capacity, while poly and wafer producers are making module production a part of their business. But do companies still face the same risks that have brought down vertically integrated solar giants in the past? Vincent Shaw reports from Shanghai.

Turkey goes vertical

A mirage in the desert or a model factory for the rest of the world? The story of how Kalyon PV established itself as a new integrated ingot, wafer, cell, and module manufacturer in less than two years is a compelling one. Götz Fischbeck visited the site to gain an insight into how it was achieved.

Copper is the new silver lining

As the PV industry scales to annual terawatt-level production to rapidly curtail the world’s emissions, it will become more challenging to continue the cost reduction trajectory. Increasing module production from current levels of 200 GW to 300 GW to several terawatts each year will consume significantly more material resources than the industry currently uses. This will require consideration of the additional materials to be sourced, writes Alison Lennon, chief scientist at Sundrive Solar and professor at the UNSW’s School of Photovoltaic and Renewable Energy Engineering.

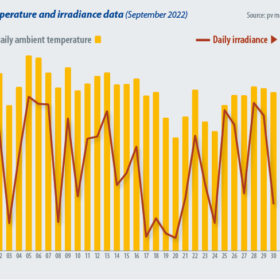

pv magazine test – September 2022 results

We are pleased to present the September 2022 energy yield results from the outdoor test field in Xi’an, China, alongside additional analysis from George Touloupas, senior director of technology and quality at CEA.

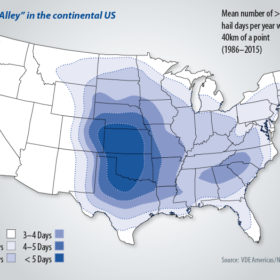

Navigating hailstorms

Owners and insurers suffered record hail losses in 2022. John Sedgwick, president of engineering advisory VDE Americas, provides some pro tips for mitigating such risks.

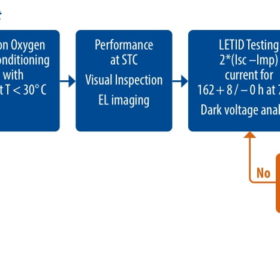

pv magazine test: Introduction to LETID testing

Together with our test partners, we have decided to add LETID testing to our set of benchmarking tests for PV modules, as the industry has improved its knowledge about the risks and mitigation of this relatively new mode of PV module degradation. George Touloupas, senior director of solar and storage at CEA, provides an update.

Vehicle integrated, in production

Producing solar products for integration into a range of electric vehicles will be a fundamentally new development and production process, says Robert Händel, the CEO and founder of Opes Solutions. The offgrid and solar mobility producer has developed its first two vehicle-integrated photovoltaic (VIPV) modules and is preparing for the market opportunity ahead.

Winds of change

The Indian solar manufacturing sector is set for a boom in the coming years, due to the country’s enormous appetite for solar and policy support in the form of import duties and local production incentives. On the technology side, a few players are already looking at n-type TOPCon cells, but their embrace by the majority has been slow to materialize, due to the high investment costs that are required. This ensures that the build-out of new PERC capacity will continue over the short term.