New processes put TOPCon under pressure

Since the concept was first introduced by Germany’s Fraunhofer ISE back in 2013, tunnel oxide passivated contact (TOPCon) cells have grown to become one of the biggest prospects for the industry to maintain a steady rise in cell efficiencies. Bringing this technology to scale, however, is not without challenges: Additional processing requirements, plus increased silver consumption, have kept TOPCon cell costs a little above where they need to be for mainstream production. pv magazine examines recent progress and the next steps for TOPCon cell production.

From the back of the pack

Southeast Asia could well become the global engine room of renewable energy expansion. Population and economic growth is expected across the three decades in which the world has to decarbonize, but the brimming bounty of renewables deployment will force developers to navigate the region’s systems. As it turns out, that could be a treacherous task.

Material concerns

Shouldn’t we all be driving in affordable electric cars with 800-plus kilometers of driving range by now? Surely yes, according to many of the announcements coming from battery scientists over the past decade. Yet for all the scientific breakthroughs, few in fact “break through” into commercial applications. Christian Kuss of the University of Manitoba makes the case for a holistic approach to battery materials development, and reminds us to look beyond the stars of the show and consider their interactions with the auxiliary materials that hold the whole thing together.

Bringing costs down to earth

Rising efficiencies and the plummeting cost of solar modules over the past few years, recent months notwithstanding, are leading innovators toward ideas that may look unusual in the current tracker-dominated world of large-scale solar parks. Advocates of the new approaches argue that they leave traditional models looking decidedly flat by comparison.

Supplying across, through APAC market segments

One year on from its spinoff from SunPower, cell and module maker Maxeon Solar Technologies is looking to supply both “across and through” the solar market segments in the Asia-Pacific region. Chris O’Brien, the vice president of APAC for Maxeon, says that the region is set to grow in importance among PV marketplaces, with opportunities on the home, business and free field.

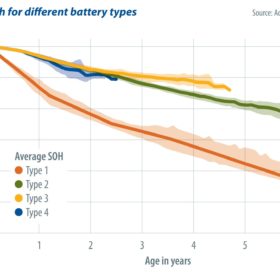

Battery performance, uncovered

Batteries are taking the energy world by storm. From residential home storage systems to large-scale installations, today’s society increasingly relies on powerful batteries. And, as we all know, with great power comes great responsibility. But, how can we ensure that our use of batteries today is responsible, cost-effective, or even safe? Kai-Philipp Kairies, CEO of Accure Battery Intelligence, shares some of his experience gained from monitoring more than 750 MWh of various storage applications.

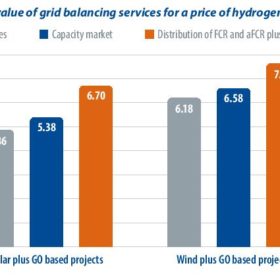

A new entrant to the energy sector

Green hydrogen can play a vital role in decarbonizing the economy and enabling countries to reach net-zero emissions. The economics of producing green hydrogen from electrolysis are maturing as developers scramble to meet expected future demand. Everoze partner Nicolas Chouleur and Neoen hydrogen expert Sacha Lepoutre discuss a case study that shows how stacking different revenue streams could improve the economics of renewable energy projects.

N-type shines when the heat is on

While n-type PV cells and modules remain a minnow compared to p-type, in some market segments and regions, its share is growing quickly. This is true in the Gulf Cooperation Council (GCC) countries, where Chinese n-type developer Jolywood has supplied key projects. Chen Jia, the deputy general manager of Jolywood, says the success is due to n-type’s natural advantages – a situation he expects to see extended to other parts of the world.

Unlocking lightweight, flex applications

Not all rooftops can bear the weight of glass PV modules. Some others have curves and shapes ill-suited to uniform, bulky panels. Flexible modules have long been advanced as the solution here, however the keys to unlocking this potential have proven elusive.

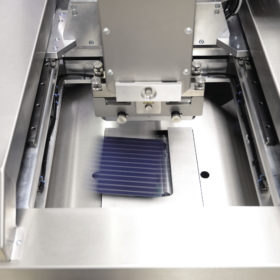

Airon looks to make HJT fly

High-quality, cost-competitive PV cell metallization will need to be flexible in terms of size, while coupled with process speed, delicate handling, and high levels of automation. So says the solar team at German cell-metallization line supplier Asys. Lukas Sänger, product manager and head of application solar at Asys, and Matthias Drews – director of solar sales – recently spoke to pv magazine about the company’s new solar platform, the Airon, and how it can achieve these goals.