Sustainable PV goes beyond recycling

Despite significant progress on material and energy efficiency in solar PV manufacturing over the last few decades, terawatt-scale manufacturing mandates further innovation and improvement along all parts of the value chain – especially on material circularity and supply chain decarbonization, according to Andreas Wade, global sustainability director at First Solar. Ensuring these objectives are met will be key to adhering to the global carbon budget for 1.5 C.

pv magazine test

November 2019 results

pv magazine test December 2019 results

The first chart to the right provides the meteo station data (irradiance and ambient temperature) for December 2019. Monthly energy yield data for the July-December 2019 period are given in the second table below. The second chart to the right shows the total energy yield of all products for December 2019.

Longi: both competitor and supplier simultaneously

With its supply of monocrystalline wafers towering over all rivals, Longi’s continuing expansion into PV cell and module production could be seen as cannibalizing some of its customers. Not so, argues Longi founder and president Li Zhenguo, who says that competition and cooperation should work in tandem.

‘We’re better off without standards’

Many factors are important in ballasting flat roof systems, such as wind speed and roof shape. In the past, however, wind force has unfortunately been underestimated, says wind expert Hans Ruscheweyh. pv magazine addressed this topic in a recent webinar with initiative partner Schletter, and drew several interesting points from the discussion.

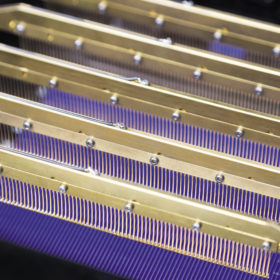

‘There will be no slowdown in capacity expansions’

Innovations in the solar industry often have a trickle-down effect. Suppliers need the ability to adapt quickly to new developments elsewhere in the market and ensure that they can move with the times. Nowhere is this more apparent than in the flashing equipment space, where in the last few years alone, bifacial and new wafer formats have quickly changed the shape of inline testing. pv magazine recently caught up with Stefan Schubert, project manager at German flasher supplier h.a.l.m. Elektronik GmbH, to discuss the latest developments in this space.

Collaborative digital fixes for the energy transition

Straddling two state borders, the West Murray region in southeastern Australia has become a microcosm of technical challenges that can plague the energy transition. Faced with serious curtailment of solar farms in this electrically remote region, a remarkable inverter-based technical feat may have changed the game.

‘It is time for Indonesia to become a solar powerhouse’

The Institute for Essential Services Reform (IESR), a Jakarta-based think tank, has emerged as a key voice calling for solar development in Indonesia. pv magazine recently caught up with Marlistya Citraningrum, the institute’s program manager for sustainable energy access, to look at what is still needed on the policy side for the archipelago nation to realize its massive PV potential.

Storage … ready?

The story of residential rooftop solar is one of liberation. Confronted with high module prices, early PV adopters experienced significantly longer payback periods – it was not unheard of for homeowners to be making monthly finance payments higher than their utility bills. But consumers were motivated, seeking independence from the stranglehold that electricity providers had on them with ever-increasing utility rates.

New inverter design coming around

Circular economy approaches in the solar industry have hitherto largely pertained to modules and batteries. Inverters, meanwhile, haven’t been in focus as much. Although these devices stand for less than 20% of the overall footprint of PV, they also contain significant volumes of valuable or toxic raw materials. Designing such products with their lifespans in mind has therefore become a critical step for the solar industry.