Making the connection

Recent years have seen plenty of innovation when it comes to cell interconnection, and the tricks manufacturers employ to boost output at this stage nowadays go well beyond simply adding more busbars, and in many new module concepts these are forgone entirely. Synergies between cell interconnection and new innovations at other stages will also be key in shaping the modules of the future.

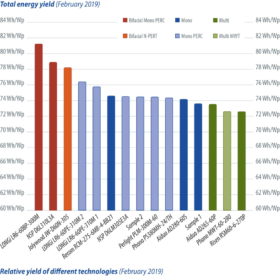

pv magazine test – February 2019 results

We are happy to present the next batch of energy yield results from the outdoor test field at Xi’an, China. The February 2019 results are presented below, with additional insight from George Touloupas, Director of Technology and Quality at CEA.

The future is complicated: BNEF Summit 2019

This year’s BNEF Summit (Future of Energy) in New York revealed that with solar and batteries continuing their historic path of price declines and exponential growth, things get much more complicated from here.

UNSW enabling terawatts of solar power

The influence of the University of New South Wales (UNSW) School of Photovoltaics and Renewable Energy Engineering spreads over the horizon like rays of sunlight through a coal haze. Its researchers are confidently working towards the time when terawatts of solar PV power people’s aspirations from Uttar Pradesh to Perth and Pennsylvania.

Perovskites step out of the labs

Michael van der Gugten, Sales and Marketing Executive at Smit Thermal Solutions, is convinced that perovskite solar cells have reached maturity, and that they are ready to make the step from the lab to production. He is leading the organization of a conference on this topic and expects that the perovskite community, production equipment suppliers and crystalline silicon cell manufacturers will discuss the implementation of perovskite-silicon tandem cells or the production of standalone perovskite modules.

Both sides of the debate

Choosing the best material to cover the backside of a module has long been a contentious issue, and the rise of bifacial technology has brought further complexity to the debate. With transparent backsheet materials quickly making their way to market, the Intersolar Europe edition of the Quality Roundtable event series sought to bring some clarity to the rear side of modules, and illuminate some of the issues that can occur in the field – both with glass-glass and glass-backsheet modules.

Next steps for HJT

There is movement in the heterojunction space, but will it be enough to surpass PERC’s momentum? New production lines show promise, but they might also be the last roll of the dice for Swiss production equipment supplier Meyer Burger.

Ms. Storage

Janice Lin is the CEO of Strategen and the co-founder of the California Energy Storage Alliance (CESA) and Global Energy Storage Alliance (GESA) trade associations, as well as the co-founding chair of the Energy Storage North America (ESNA) conference. Lin is also in the process of setting up a new nonprofit organization, the Green Hydrogen Council. Just after she received The Cleanie Awards’ Entrepreneur of the Year award, pv magazine caught up with her at Smart Energy Week and SPI 2019.

‘There is a great unmet need in this industry for differentiation’

With its second U.S. production facility coming online in October, First Solar is claiming the title of the “largest module manufacturer in the Western Hemisphere,” and reports that the Series 6 module it introduced in 2018 is now sold out through to the middle of 2021. pv magazine caught up with First Solar CEO Mark Widmar in Berlin recently to discuss the latest developments in the global module market and the company’s plans for the future.

Taking the lead

This quarter, pv magazine‘s UP Initiative focuses on lead – a toxic heavy metal that’s present in many PV technologies, and one that’s often mentioned in connection with hazardous substances across the green energy supply chain. We take a closer look at the issue and ask what it would mean for manufacturers to replace lead in their modules with more environmentally friendly materials.