Polysilicon & Wafer Rankings 2016

C-Si manufacturing: Demand is looking strong for both polysilicon and crystalline silicon wafers, as analysts expect that another rush for installations is imminent, ahead of China’s latest feed-in tariff cut in July. Demand for monocrystalline wafers has increased, but manufacturing trends still leave space for high performance multi-wafer.

2017: a year for PERC & Black Silicon

Module trends: As China looks set for another big year of installations, the biggest module manufacturers are consolidating their market share, with the top 5 manufacturers set to represent more than 40% of global shipments. Mono PERC and diamond wire cut Multi combined with black silicon are set to be the dominant trends in technology.

Shaving cents off wafers

pv magazine Germany award: The end consumer market is where the action is these days in Germany’s energy transition. But keeping the ball rolling depends on keeping PV affordable. A German production equipment manufacturer has new method that promises significant cost reductions.

Solar goes corporate: the rise of the bilateral PPA

PV power plants: Corporations want in on the falling costs and predictable prices of wind and solar. Bilateral power purchase agreements have emerged as one new business model among several that businesses are employing as they get serious about renewable energy, both in the United States and abroad.

Faltering funds

Solar sector funding: Total corporate funding into the solar sector declined substantially in 2016 compared to 2015 and even 2014, with solar demand expected to reach an all-time record high. Several factors, policies and events made 2016 a volatile year for the sector with plenty of positives and negatives.

Power to the people

Distributed storage costs: With the average payback cost of a home battery storage system sticking stubbornly at around ten years, skeptics remain unconvinced that mass-market adoption of distributed storage is on the cards any time soon. So what measures is the industry taking to expedite cost reductions, improve storage technology, and shift the conversation from a ‘nice to have’ to a ‘must have’?

An iconic badge for batteries

Battery production: In future all of the lithium-ion batteries for Daimler AG will come from the German town of Kamenz. That also goes for batteries for stationary applications, which since last year have borne the Mercedes-Benz name. pv magazine paid a visit to the plant, which was built in 2009. Daimler was the first company to use this technology in an automobile.

Powerful PV in, and from, China

When China switched on to solar, it changed our industry forever. China’s role as the PV manufacturing powerhouse is well established. However, industry observers, analysts and market participants are still unsure how China’s position as the largest solar end market is being digested.

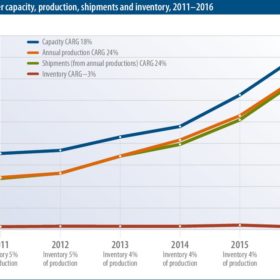

The shipment shuffle

2016 PV manufacturer shipments: Understanding the vagaries of the global solar market’s actual size and pressure points is a nontrivial undertaking. From headline GW-level installation figures through to regional cell capacities and actual inventory levels, getting a firm grasp of what is available to the market has never been more important.

Learning how to read a learning curve

Market analysis: The last edition of the International Technology Roadmap for Photovoltaic (ITRPV) roadmap addressed the end of the learning curve for PV modules as we know it. What lies behind the end of the learning curve is also the end of a common belief: industries cannot always be compared and PV is no exception to a common Shaddock-style rule: “if you believe you know what is going to happen, then you did something wrong”, argues Becquerel Institute co-founder and director Gaëtan Masson.