Out on the water

The rise of floating PV: Floating solar power solutions have emerged from a niche oddity to mainstream baseload; the latest Chinese tender set covers 1 GW worth of projects, potentially the new normal for FPV. Indeed, Ciel & Terre, the current market leader, says there could be 3 GW of FPV by 2020, per analysts’ predictions.

PID, soiling and module degradation in hot climates

PID in India: In the cost-conscious Indian solar sector, ensuring reliable power output should be the number one priority. However, an example of one solar farm suffering from the ill-effects of under-performing modules, installation malpractice and unsatisfactory maintenance shows how corner cutting from the outset is more damaging in the long run.

Spend a little, gain a lot

7th Quality Roundtable: pv magazine’s is bringing its Quality Roundtable format to Renewable Energy India this month to spark informed and engaging discussions about the key quality issues facing the country’s surging solar sector. PI Berlin’s Steven Xuereb will be among those presenting a topic for discussion, and here is a sneak peek at what to expect.

Building to become more competitive

India manufacturing: India will soon become the world’s third-largest solar market, surpassing Japan for annual installations. However, it has reached these heady heights on a foundation comprised of largely imported solar components from China, while the domestic manufacturing market remains underdeveloped. How might this change in the near future?

Retrofit for purpose

Junction box potential: Recent safety regulation updates in the U.S. and Europe could render vast swathes of rooftop solar installations non-compliant with new fire codes, potentially opening up a retrofit market for providers of components that can make arrays compliant. One cost-effective approach could well be the replacement of older junction boxes with newer, more sophisticated devices.

Prodding new markets

Module assembly: As solar PV becomes more accessible and affordable across the globe, more nations are turning to local PV manufacturing in a bid to stimulate the development of their renewable energy markets. Against the backdrop of tightening competition and rising quality expectations, pv magazine sheds light on emerging solar module manufacturing locations and their chances against mayor upstream PV hubs.

DEGER: an introduction

Solar trackers: The solar tracking market has never been more competitive or confident. As the solar industry grows, trackers are becoming a more vital component of ground-mounted PV plants. Here, Germany’s DEGER talks about tracking technology, the industry, and their own journey of innovation.

Momentum builds for HJT

Cell production: While an inherently conservative business, PV cell production has evolved greatly in terms of cost and efficiency. Heterojunction cell architectures represent more of a step change, when compared to the PERC investment cycle currently underway. In this first of a two part HJT focus, pv magazine speaks to some of the leading technology providers for the high efficiency concept.

The new module test

Module reliability: pv magazine’s new module test is kicking off. The first candidate is Jolywood with its bifacial n-Pert module. The test is designed to help investors in their module purchasing process, while at the same time allowing manufacturers to spot problems and improve their production processes.

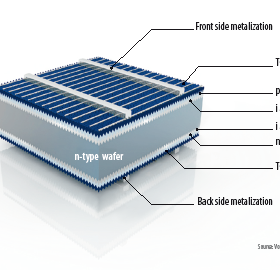

Jolywood JW-D60N module

With its JW-D60N module, Jolywood has implemented several state of the art technologies. The module cells employ n-type wafers, which allows higher efficiency and mitigates light induced degradation during the first 1,000 hours of illumination. This is a risk always present for p type cells, and may cost a few percentage points of energy yield. […]