Editor’s Pick

As the year draws to a close, our editors are looking at what new and riveting technological advancements it has brought, and which technologies have risen to the top, despite market challenges.

Grid parity’s muddy trails

Europe’s new breed of grid parity projects is mushrooming on the southern fringes of the continent. With governments’ flexible attitude towards remuneration, to the detriment of reliable planning, the desire to make grid parity projects work is strong, and its progress will likely spread north.

The time is right

Kaco is launching a mass-produced string inverter with silicon carbide switches onto the market following 10 years of discussion about the technology within the industry. In the 100 kilowatt plus segment, the technology produces small, lightweight devices with few components.

Raising the bar with U.S. roundtables

pv magazine’s Quality Roundtable and Future PV Roundtable at Solar Power International allowed for thorough examination of a number of key trends in our industry.

Downside of good times Down Under

In 2018 and 2019 combined, Australia is set to double its cumulative installed PV capacity. The speed at which installations are being realized is having implications for quality that, if not addressed, could leave project investors, lenders, businesses, and homeowners regretting their decision to go solar. The first pv magazine Quality Roundtable at All Energy Australia in October fostered discussion of these issues, finding that time is of the essence.

TOPCon boosts demand for EU equipment

Photovoltaic manufacturers in Asia are importing deposition reactors from the EU to test the latest word in silicon solar cell passivation. Two thin buffer layers sandwiched between silicon wafers and metal contacts are increasing the efficiency of conventional solar cells and setting new records. Equipment suppliers expect the technology to spread through the industry and boost their bottom line.

Materials matter

As problems with component failure have already laid bare, there is a clear need for contract clarity at every stage of a PV project, from material and component sourcing to power purchase and operations agreements. Here, pv magazine investigates a little covered issue for module buyers, which could threaten insurance coverage and the overall success of a project further down the line.

New technologies move to the back

The tension between the cost cutting and performance boosting opportunities presented by new technologies and the tendency for risk aversion is never more evident than in PV module materials. This applies nowhere more than in backsheets, where new innovations are big on promise, but must convince manufacturers and the market of their long-term performance.

Fit for the 21st century

Co-extruded backsheets are opening up novel circular possibilities for the solar industry, as well as driving durability and lowering costs, writes Netherlands-based materials specialist DSM.

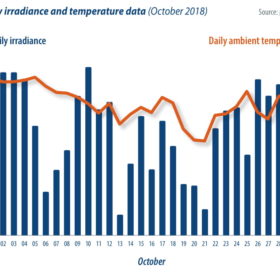

pv magazine outdoor test

October 2018 results

We are happy to present to pv magazine readers with the next batch of energy yield results of the outdoor test field at Xi’an, China. Since the November issue, we have been showing the results of the month that precedes the issue by two months, so the October results will be presented in this issue.