Making sense of new sizes

The era of large modules has arrived, but it shouldn’t be assumed that this will immediately make projects more profitable, argues Steven Xuereb of engineering service provider PI Berlin, as he compares different module size options for a current development project.

Unplugged

An O&M provider to a project in northern Germany has been left scrambling to acquire replacement connectors after a series of failures. pv magazine investigates the case and finds that it all could come down to a simple click (or was it two?).

FPV’s important role

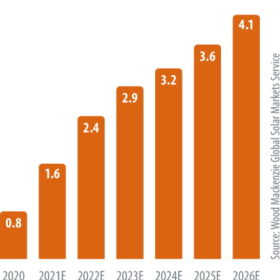

Molly Cox details Wood Mackenzie’s research showing that floating PV installations will continue to grow as the niche industry finds its large- scale fit with utility companies, large communities, companies, and municipalities – wherever the right waters are to be found.

Floating up to standard

Floating PV is a growing market, especially in Asian countries with land pressures. However, like many promising niches, it is growing faster than the standards surrounding it. With installed floating PV capacity set to double in 2021, a raft of various and sometimes competing standards are being floated, but the question remains – what is truly the best way forward?

Your solar+storage business plan

With many developers now working on solar+storage projects, it’s time to look more closely at specific business plans. Siobhán Green, lead on battery storage in continental Europe for Everoze, looks at three key questions.

A PV band-aid

DuPont has developed a repair kit for PV modules with backsheet failures. Cracked and chalking backsheets can cause problems for solar project owners, but this could easily be addressed in the field without swapping out the PV modules. Stéphan Padlewski, regional marketing leader EMEA at DuPont Photovoltaic Solutions, spoke to pv magazine about how the solution works.

China struggles with solar supply

Since July 2020, the PV industry has been experiencing price rises, which have affected almost all the components in a solar system. As these price increases spill out into higher installation costs, we see end user prices for solar rising for the first time in 10 years, threatening the competitiveness of PV in certain markets. Vincent Shaw reports from Shanghai on solar manufacturing’s supply chain crisis.

New processes put TOPCon under pressure

Since the concept was first introduced by Germany’s Fraunhofer ISE back in 2013, tunnel oxide passivated contact (TOPCon) cells have grown to become one of the biggest prospects for the industry to maintain a steady rise in cell efficiencies. Bringing this technology to scale, however, is not without challenges: Additional processing requirements, plus increased silver consumption, have kept TOPCon cell costs a little above where they need to be for mainstream production. pv magazine examines recent progress and the next steps for TOPCon cell production.

Firm foundations on shifting sands

Unprecedented capacity expansions and massive technology changes, all happening at a frantic pace, signal that PV is entering the terawatt era. However, challenges in supply and demand imbalances across the value chain, combined with emerging technical and quality risks, require detailed analysis and due diligence from buyers to avoid pitfalls, according to George Touloupas, Joseph Johnson, and Aditya Vardhan from Clean Energy Associates.

Custom standardization: unlocking BIPV

The creativity of architects and the need to standardize BIPV products to bring costs down may appear mutually exclusive. In reality, they are the concurrent needs of both the construction and solar sectors and must be considered for the promise of “PV everywhere” to become a reality in our built environment. Work is underway to bridge this gap and the initial results are building in innovation.