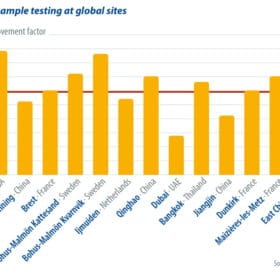

Time to standardize

Not all quality control plans, processes and agreements are created equal, writes Frédéric Dross, the VP of strategic development for Senergy Technical Services (STS). Indeed, developers can find themselves saddled with agreements that allow unacceptably low levels of quality, unless they have followed standards.

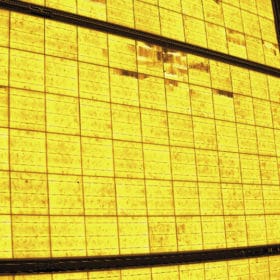

Curtailing corrosion: making mounting structures last

Raw material quality is vital for solar power plants, particularly given higher expectations for their lifetimes, as 30+ years is becoming increasingly common for PV arrays. Steel is the main structural material used in such installations today, so the use of quality protective coatings in their construction has never been more important, writes Jérôme Guth, the solar segment leader for ArcelorMittal Europe.

Microcracks and module design

New cell and module technologies are boosting power outputs, but they often have implications for quality. A focus purely on cell cracking illustrates just this point, with some approaches proving beneficial, and others potentially problematic – cue Tristan Erion-Lorico from PV Evolution Labs (PVEL).

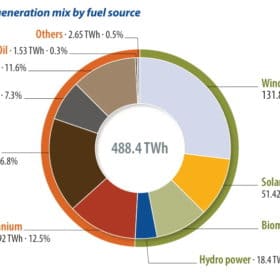

PV feed in, certified

As more renewable energy capacity is built, commissioned, and connected, grid stability concerns are driving rapid regulatory changes. In the European Union, regulatory changes are now building momentum. As the first mover, Germany has shown that achieving compliance can initially seem burdensome, but it can quickly be integrated into existing processes and platforms.

Flexible tools for the next generation

A solar manufacturing investment cycle appears to be underway in Europe, with equipment suppliers reporting surging levels of inquiries for new production lines. Larger PV wafer formats are driving the change, along with renewed confidence in the outlook for the solar PV market on the continent. To meet the demand, European equipment suppliers are now embracing flexibility.

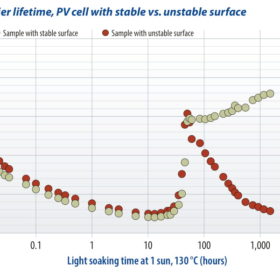

A deeper understanding of LeTID

Australia’s University of New South Wales (UNSW) has built a reputation for strong collaboration with the PV industry, from cell passivation through to the causes of degradation. Malcolm Abbott, a senior research fellow, directs one of the UNSW teams that is continuing its work into light and elevated temperature-induced degradation (LeTID). He recently spoke with pv magazine to provide an update.

Pretty stressful – PID trials on the test bench

To find out whether a module is susceptible to potential-induced degradation, you can conduct stress tests in a climate chamber. These tests are designed to induce potential-induced degradation and reach stress levels at or beyond what a module would likely experience in the field. That is what the standard says, at any rate. But researchers at Germany’s Center for Solar Energy and Hydrogen Research have now confirmed long-standing doubts about the reliability of the standard test for highly stressed modules in 1,500 V power plants. One solution is tougher testing and better materials selection.

Pushing POE for longer module lifetimes

Polyolefin-based films are estimated to represent around 20% of the market for PV module encapsulation materials – a share that has been growing each year since 2017. The challenge of potential-induced degradation in bifacial modules has thus far driven this shift, but polyolefin has plenty more to offer in ensuring long-term performance for PV modules. pv magazine recently caught up with Yuyan Li, technical leader for PV applications at Dow Packaging & Specialty Plastics – the supplier of Engage PV POE resin – to discuss the latest developments in the PV encapsulants market.

Unchained: Political moves shift solar supply

PV module supply chains to the U.S. industry are in flux, and not for the first time. Moves to take action alongside stimulus measures aimed at clean energy are changing the way in which U.S. developers and installers source modules, writes David Wagman, senior editor of pv magazine USA.

ESG criteria: Should developers take notice?

Something is brewing in the financial world. “Sustainable finance” and the growth of ESG funds have been taking the market by storm in recent years. Since most major PV projects end up needing investors from the capital market, it is only a matter of time before they will have to adapt. The beginning of March 2021 saw a milestone reached in this process.