Backtracking is becoming smart, but it isn’t magic

Higher energy yields and a better distribution of generation over the day are the two key advantages that explain the success of single-axis trackers for PV generation in sunny places like Southern Europe, the Middle East, North Africa, or North America. As the scale of new tracker projects is increasingly reaching hundreds of megawatts, finding suitable large plots of affordable, flat land is not as easy as before. Everoze partner Felipe Canto Teixeira highlights the increased complexity in the design and energy assessment created by more challenging topographies, and discusses solutions based on his on-the-ground experience in hilly Portuguese terrain.

Bringing space solar back to earth

The integration of solar into the rooftops of electric vehicles is an opportunity for PV, but it could also drive the development of very high-efficiency semiconductors, says Rupert Kogler, from development glazing, roof, and components at Webasto, a top 100 automotive supplier.

E+V = better vehicles

Electric vehicle batteries are packed with energy, with additional battery density and efficiency working to quell range anxiety for drivers. But with that capability lingers a concern from some that EVs may pose a fire risk and a challenge for first responders in the event of accidents. Professor Ray Wills from Future Smart Strategies bought his first EV in 2012 and argues that in terms of safety, EVs remain an easily superior vehicle, and even the tiny fire risk that exists is an ever-diminishing issue.

The time is now

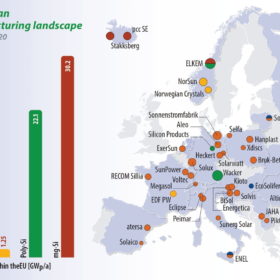

European solar manufacturing is back on the agenda after over a decade of minimal activity. Ambitious proposals are in place to reactivate a booming industry with investment earmarked, factories planned, sustainability goals announced, and political strategies outlined to support the projected growth of PV installations. Can these plans be realized? The UP Initiative will spend the second quarter delving into these questions.

The pieces that make China’s PV puzzle

Last year was a disappointing period for China’s PV industry, as high module prices restrained domestic demand and the ongoing pandemic continued to cause upheaval. This year looks more promising, even though the pieces of China’s PV puzzle have yet to fall into place. But sorting through them allows for a better understanding of the world’s largest PV market, reports Vincent Shaw, pv magazine’s China correspondent.

The right time for TOPCon

The potential advantages of n-type technologies have long been known to solar manufacturers, and such applications have been the focus of much of their research and development activities. Recent developments see 2022 shaping up as the year when n-type goes into mass production, led by tunnel oxide passivated contact (TOPCon) cells. pv magazine takes a closer at this cell technology and its route to the mainstream.

The path to the TOPCon

Through tunnel oxide passivated contact solar cells, a new route to high efficiency is becoming clear. But at present, there are many routes that manufacturers can take in production. Need a map? Jonathan Gifford attempts to find his way through.

Winds of change

The Indian solar manufacturing sector is set for a boom in the coming years, due to the country’s enormous appetite for solar and policy support in the form of import duties and local production incentives. On the technology side, a few players are already looking at n-type TOPCon cells, but their embrace by the majority has been slow to materialize, due to the high investment costs that are required. This ensures that the build-out of new PERC capacity will continue over the short term.

Made in Indonesia

Indonesia has set itself some ambitious goals for PV manufacturing, backed by domestic content requirements and other incentives. But local demand is limited, and the nation faces stiff competition from China and other countries on the export market. While real obstacles remain, a restructuring of state-owned electricity company PLN and local raw material riches mean the potential is growing.

Solar manufacturing’s new horizons

With supply chain and sustainability concerns an increasing feature in the solar industry, and demand for new PV installations around the world only increasing, multiple regions are looking to establish their own manufacturing base. Alongside this, cell and module makers are gearing up for a switch to n-type technologies: all of which mean fast moving developments for Europe’s PV equipment suppliers. pv magazine caught up with Thomas Kießling, senior product expert at 3D-Micromac for a look at market and technology prospects for the company’s laser cell cutting equipment in 2022.