The SolarWinds of change

Solar inverters have gotten smarter. The recent hacking of U.S. government agencies via software provided by SolarWinds has triggered discussion about whether inverters, with all their added functionality, could pose a serious cybersecurity threat to solar PV projects. David Wagman, senior editor at pv magazine USA, looks at the efforts that are underway to stay one step ahead of potential hackers.

An endless appetite for PV

With growing demand for healthy fruit and vegetables, both plastic and glass greenhouses are increasingly supplying Chinese tables. Rene Moerman, the founder of China-based Xilia, toured a number of sites where solar PV has been integrated into greenhouses.

Raspberry PV protects the crop and avoids waste

An agrivoltaic project in the Netherlands demonstrates the compatibility of solar PV power generation and raspberry cultivation. The solar roof protects the plants, saves the farmers work, and only has a minimal impact on the harvest.

Agrivoltaics: Where are we heading?

The complexity of agrivoltaics is not rocket science, but rather lies in the field’s various interdisciplinary challenges, says Max Trommsdorff, head of group agrivoltaics at Fraunhofer Institute for Solar Energy Systems ISE. Should agrivoltaics be deployed with interspace cropping, or should we use stilted PV systems that allow for cultivation below? And can the sector flourish without regulation?

Leveling the playing field

Tensions are heating up throughout the world over the issue of forced labor. Calls are increasing for supply chain transparency, and recently published EU draft legislation on corporate due diligence and accountability should improve upon the currently available voluntary measures, which have been described as largely ineffective. With this in mind, pv magazine’s UP Initiative will spend the second quarter of 2021 looking at what solar and energy storage companies can do to lead by positive example when it comes to the workers who are involved in the production of their products and services.

History repeats

“Unprecedented” was a term widely used in 2020, as the world grappled with the Covid-19 pandemic. The same word can be similarly applied to the plans and investments in production capacity announced by Chinese PV manufacturers right across the supply chain. But what shape are these expansions taking and what is driving this renewed confidence? Vincent Shaw reports from Shanghai.

Bifacial drives encapsulant switch

Suppliers of encapsulant materials – plastic sheets that are heated to laminate together the components in PV module stacks – are rapidly expanding to keep pace with module manufacturing in Asia and other parts of the world. Ethylene-vinyl acetate (EVA) continues to dominate the market, but new developments in module technology are driving a slow shift to more costly polyolefins.

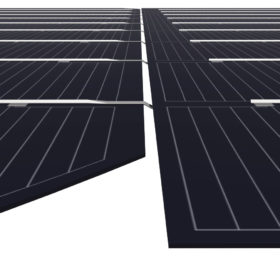

Clever by half

Enhanced module appearance and power output can be achieved by a smart cell interconnection technique Longi is employing in its Hi-MO5 module series. But as with all new technologies, there are potential pitfalls.

New pathways in flexible thin film

Having picked up GBP 5.8 million ($8 million) in a series of investments, U.K.-based Power Roll is pushing ahead with pilot production of an innovative new thin film with which it can manufacture both solar modules and capacitors. In the future, the design could also bring the potential for solar generation and energy storage within a single lightweight device.

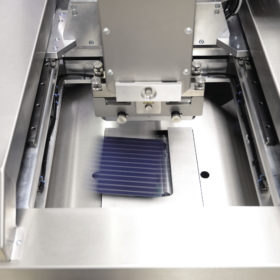

Airon looks to make HJT fly

High-quality, cost-competitive PV cell metallization will need to be flexible in terms of size, while coupled with process speed, delicate handling, and high levels of automation. So says the solar team at German cell-metallization line supplier Asys. Lukas Sänger, product manager and head of application solar at Asys, and Matthias Drews – director of solar sales – recently spoke to pv magazine about the company’s new solar platform, the Airon, and how it can achieve these goals.