Bangladesh sets solar import standards

Complaints about sub-standard, cheap PV imports from China – and notably, India – have been heeded by Dhaka, which has issued a requirement for modules, inverters, charge controllers and batteries to attain IEC electrical standards.

Longi demonstrates 20% bifacial boost

In a white paper published this week, Chinese module maker Longi Solar shares six months of data from a testing site in India that was built in cooperation with German testing institute TÜV Rheinland. The results show energy yield gains of around 20% for both bifacial mono PERC and n-type modules.

Bangladesh extends incentive scheme for domestic solar industry

PV manufacturers receive 10% of the value of their exported products as an incentive and the nation’s central bank has extended the program to cover this financial year. Bangladesh’s solar manufacturers have called for more, however, and point to more generous schemes to the west.

Bangladeshi industrial sector embraces leasing model for solar rooftops

The affordable public financing packages on offer for solar rooftops are attracting developers who have clients happy to lease out roofspace without any capital outlay in order to secure cheaper power.

Sub-standard PV equipment worries Bangladeshi solar developers

Visitors to this year’s Solar Bangladesh Expo have called for the implementation of quality standards on solar imports – action which the government is currently pursuing – with one industry insider rubbishing Indian-made products.

Longi unveils results of bifacial module test

The exercise, conducted on Longi PERC bifacial modules by Germany’s TÜV SÜD at a test field in China, showed surprisingly higher gains in panels getting light reflection from painted-surface and grassland albedo. It also showed, Longi claimed, bifacial panels operate at lower temperatures than single-sided alternatives.

A common language for bifacial PV

This week pv magazine was in Amsterdam for the sixth edition of the BifiPV workshop, where the discussion focused on the impressive achievements made by bifacial solar modules and the challenges the technology faces as it moves toward mainstream adoption.

‘Mono will supply 80% of the world’s solar by 2021’

Polysilicon manufacturer Daqo has announced the start of pilot production in Xinjiang and expects to ramp up to full output by the end of the year, doubling the company’s annual capacity to 70,000 MT. Some 90% of its poly will be mono by that stage and Daqo expects 40% to be suitable for n-type products next year.

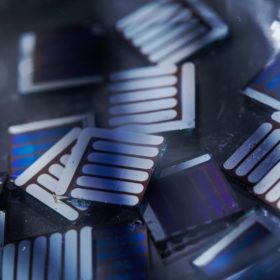

Canadian Solar raises efficiency record for mono cast cell

The result was verified by Germany’s Institute für Solarenergieforschung GmbH. The Canadian-Chinese manufacturer claims to have achieved 22.8% efficiency for its multi-crystalline P5 cell, produced with a mono cast manufacturing process.

Silicon and perovskites should stick together, say Korean scientists

Researchers from the Ulsan Institute of Science and Technology have demonstrated a new method of fabricating perovskite-on-silicon tandem devices, using a transparent conductive adhesive to combine the two cells. The scientists have developed devices with demonstrated efficiencies of 19.4%, and propose strategies to bring that above 24% using existing technology.