Glint Solar unveils software for early-stage BESS projects

The Norwegian PV planning software company has released a new product for prospecting, analysis, and design of battery energy storage system (BESS) projects at the early stage.

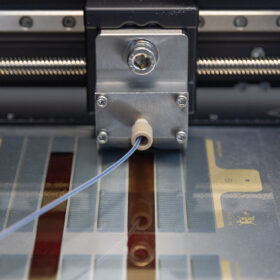

InfinityPV unveils slot die coater for thin-film PV research

The customizable, compact sheet coater supports coating speeds from 1.2 mm/sec up to 33 mm/sec.

Using laser processed glass as solar concentrators for BIPV

Researchers from Aalto University in Finland demonstrated a proof-of-concept of laser-processed glass to be used as a type of solar concentrator for building integrated PV (BIPV) applications. The treated glass enabled a 55-fold increase in photocurrent generation compared to unprocessed glass, with an estimated optical efficiency of 0.66 %. Additionally, a fluoropolymer coating was applied to create a self-cleaning surface.

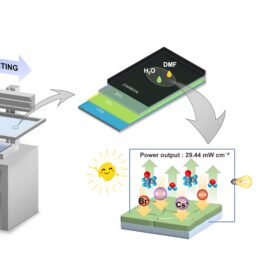

Chinese scientists improve carbon perovskite solar cell performance via dual-solvent process

A team of researchers in China has demonstrated a novel dual-solvent process in 4-terminal carbon CsPbBr3 perovskite solar cells that achieve 10.18% power conversion efficiency. They have also built a large area 17.88 cm2 device achieving an 8.72% efficiency while retaining 93.2% of the initial performance after 1,000 hours of operation at 150 C.

Chinese PV Industry Brief: GCL completes switch to FBR polysilicon production

GCL Technology has posted CNY 15.1 billion ($16.7 billion) in revenue and a CNY 4.75 billion net loss for 2024. The Chinese polysilicon and solar module manufacturer says its current annual capacity is 480,000 metric tons (MT).

Multi-constraint modeling for agrivoltaics

Researchers at Cornell University in the U.S. have developed a novel optimization model for agrivoltaic site design and benefits, which was demonstrated using irrigation-optimization relative to economic and environmental goals.

MCPV secures €10 million grant for 2.5 GW solar module factory in Spain

Netherlands-based MCPV, a silicon heterojunction PV manufacturer, is planning to build a GW-sized PV panel factory in Tudela, Navarra, Spain.

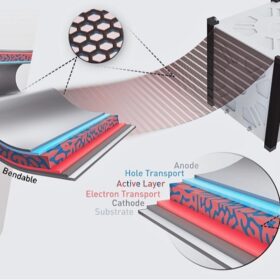

Turkish startup developing perovskite-organic tandem solar cell tech

Spacelis is developing lightweight, rollable space-grade perovskite-organic tandem solar PV technology targeting space and terrestrial portable energy applications.

Chinese PV Industry Brief: Tongwei secures $1.38 billion for polysilicon business

Tongwei says it will bring in strategic investors for its polysilicon subsidiary, Sichuan Yongxiang Co., raising CNY 10 billion ($1.38 billion) at a CNY 27 billion valuation, with investors acquiring a stake up to 27.03%.

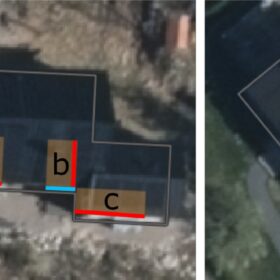

Using LiDAR data to improve modeling of PV system tilt, azimuth

Researchers in Sweden have developed a method to use LiDAR data to enable more precise tilt and azimuth modeling of solar PV and solar thermal capacity at a regional or substation level. The model could enable aggregators and grid operators to improve grid planning.