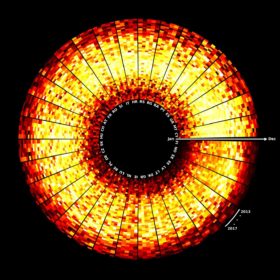

A worldwide, open source model for solar performance

Researchers at Denmark’s Aarhus University have created a modelling tool which they say, by taking into account weather data and the historical performance of PV installations, can precisely predict the output of a solar plant at any location. The tool, say the academics, will help with the planning of new installations and the integration of PV into energy systems.

Battery scientists make a cracking observation

Scientists at the Georgia Institute of Technology in the U.S. used x-ray imaging to observe cracks forming in a solid state lithium battery, a discovery they say changes the understanding of performance of solid state batteries and which could lead to more durable systems.

Italy’s FuturaSun opens 500 MW module fab in China

The company has opened a 500 MW factory in Jiangsu province. The fab will produce monocrystalline multi-busbar modules and, according to FuturaSun, plans are already under way to double its capacity as it continues to take the fight to the big boys.

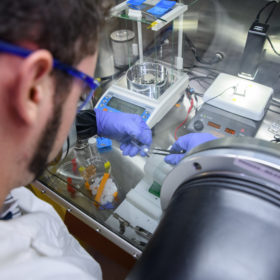

Researching some cool new battery materials

Scientists from China and the United States have developed an additive for electrolyte materials they say could improve the operating temperature range for lithium-ion batteries, allowing them to operate down to minus 40 degrees Celsius without compromising performance at temperatures up to 60 degrees Celsius.

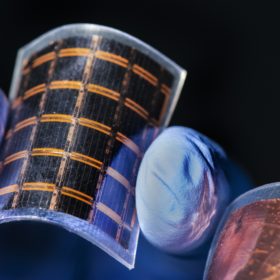

The weekend read: One side or two

Bifacial modules are here to stay. But even as manufacturers commit further capacities to two-sided module production spanning a whole range of technologies, there are still challenges to overcome, to fulfill predictions that bifacial will represent almost 40% of all modules produced inside the next decade. Flash testing conducted at the end of cell and module production presents one of these, and there is plenty of debate among equipment suppliers as to how this manufacturing stage should treat bifacial cells and modules.

EPFL scientists put perovskite through its paces

Scientists working at Switzerland’s École Polytechnique Fédérale de Lausanne, in the lab of renowned PV scientist Michael Grätzel, have developed a new method for testing perovskite solar cells that they say combines the advantages of laboratory and outdoor testing and will contribute to the creation of industry standards for characterizing perovskite stability.

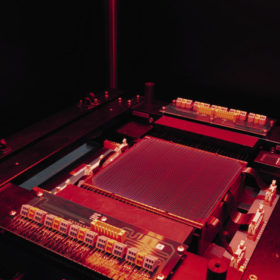

Solid (state) plans announced by imec

Belgian research institute imec this week said it has set a performance record of 400 watt-hours per liter – at a charge rate of 0.5 – for a solid state lithium metal battery. The institute says it is working with the University of Hasselt to scale up production of solid state cells on a pilot line in Belgium.

Well it’s Swan for the money…

This year JinkoSolar launched its bifacial Swan module, one of the first to feature a transparent Tedlar backsheet made by DuPont. pv magazine had the chance to catch up with Gener Miao, JinkoSolar VP for global sales and marketing for an update on the module’s innovations, and on how the company sees solar markets this year.

MIT works to refine the flow of promising perovskites

Scientists at the Massachusetts Institute of Technology have developed an accelerated process for screening new perovskite compounds as they search for those with the potential to be used in high efficiency solar cells. According to MIT, the process speeds up the synthesis and analysis of new compounds by a factor of ten and has already highlighted two sets of materials worthy of further study.

Nothing can bring down the price of III-V solar cells – just add germanium

A research paper from scientists at the U.S. National Renewable Energy Laboratory outlines a new approach to the production of gallium arsenide based cells. The approach, termed ‘germanium on nothing’, could enable the cost effective, high volume production of PV cells based on III-V materials such as gallium arsenide.