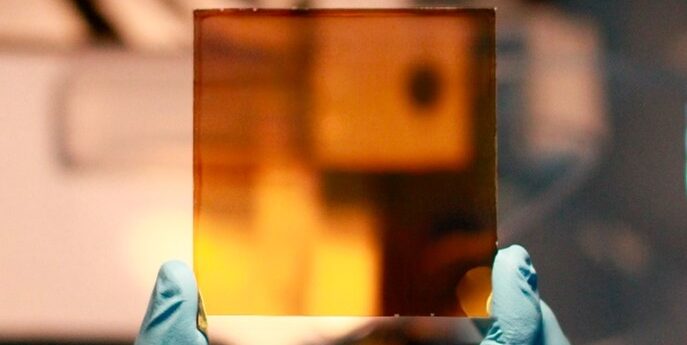

An international research team from China, Germany, Japan, and the United States has found a method to economically synthesize and stabilize conductive colloidal quantum dot (CQD) inks. The material was used to make quantum dot films in large-area PV devices measuring 12.60 cm2 with a certified efficiency of 10%, with lab-sized cells achieving a 13.40% efficiency.

CQD technology has been proposed in the past as a potentially low-cost, high-efficiency thin-film alternative to traditional silicon PV, but low-yield synthesis processes, uncontrollability, material instability and relatively high costs have blocked progress.

“Our project successfully achieves both low-cost processes and large-area CQD film printing, effectively bridging the gap between high costs and commercialization viability,” corresponding author, Zeke Liu, told pv magazine. “The novel aspects of our research lie in integrating the most advanced, cost-effective CQD synthesis technique: the direct synthesis (DS) of conductive CQD inks with a solution chemistry engineering (SCE) strategy for the improvement of ink stability.”

Noting that the approach optimizes ionic configurations and surface structure, “significantly” minimizing the irreversible CQD aggregation and fusion, Liu said, “These innovations enable single-step printing of high-quality, large-area CQD films at a fraction of the cost, making commercial-scale CQD photovoltaics far more viable.”

The researchers identified an “intrinsic correlation” between irreversible quantum dot aggregation, nanoscale morphological evolution, and resultant morphological defects and its “decisive role” in the performance of large-area films. In the experiments that tested dispersions in a range of solvents, the scientists described creating an “iodine-rich environment in weakly coordinating solvents” and converting “iodoplumbates into functional anions, which condense into a robust surface shell” to yield the stable inks.

Subsequently, the solution-chemical-engineered (SCE) approach for CQD films was validated in both large-scale CQD solar devices and lab-scale devices. “We achieved a certified power conversion efficiency (PCE) exceeding 10% for large-area modules and 13.40% for small-area cells, setting new benchmarks while reducing material costs to less than $0.06/Wp,” said Liu. The certification of the CQD solar cells was done by the National Center of Inspection on Solar Photovoltaic Products Quality (CPVT).

The validation was in solar cells with a stack that included a CQD matrix sandwiched between zin oxide (ZnO) nanocrystals and a p-type polymer material (PBDB-T). Slot die coating was used for the film deposition, except for the indium tin oxide (ITO) on the glass substrate and the silver (Ag) anode steps. Standard stability tests in ambient air revealed that the PV devices based on SCE inks had operational stability for up to 50 days.

When asked about future research activity, Liu said that researchers will aim to scale the CQD inks, enhancing the efficiency of the CQD solar cells and broadening their applications. “We will explore adapting the technology for various quantum dots, including low-toxicity variants, and for use in flexible electronics,” said Liu.

Other topics such as CQD potential for near-infrared detectors and short-wave infrared (SWIR) sensors will also be investigated, according to Liu who sees the potential for use in artificial intelligence (AI) applications, such as autonomous vehicles and industrial automation.

The new solution was presented in the paper “Overcoming efficiency and cost barriers for large-area quantum dot photovoltaics through stable ink engineering,” published in nature energy.

The research team had members from China-based Soochow University, Shenzhen Technology University (SZTU), South China University of Technology, Yunnan University, as well as from Japan’s University of Tokyo and University of Electro-Communications, Hitachi High-Tech Corporation. It also included academics from Germany’s Friedrich-Alexander Universität Erlangen-Nürnberg, Helmholtz Institute Erlangen-Nürnberg for Renewable Energy, Technical University of Munich, and USA-based Northern Illinois University, Argonne National Laboratory, and National Renewable Energy Laboratory.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.