German startup Solyco has presented a new low-temperature solar panel interconnection technique that does not require the use silver, lead, or bismuth.

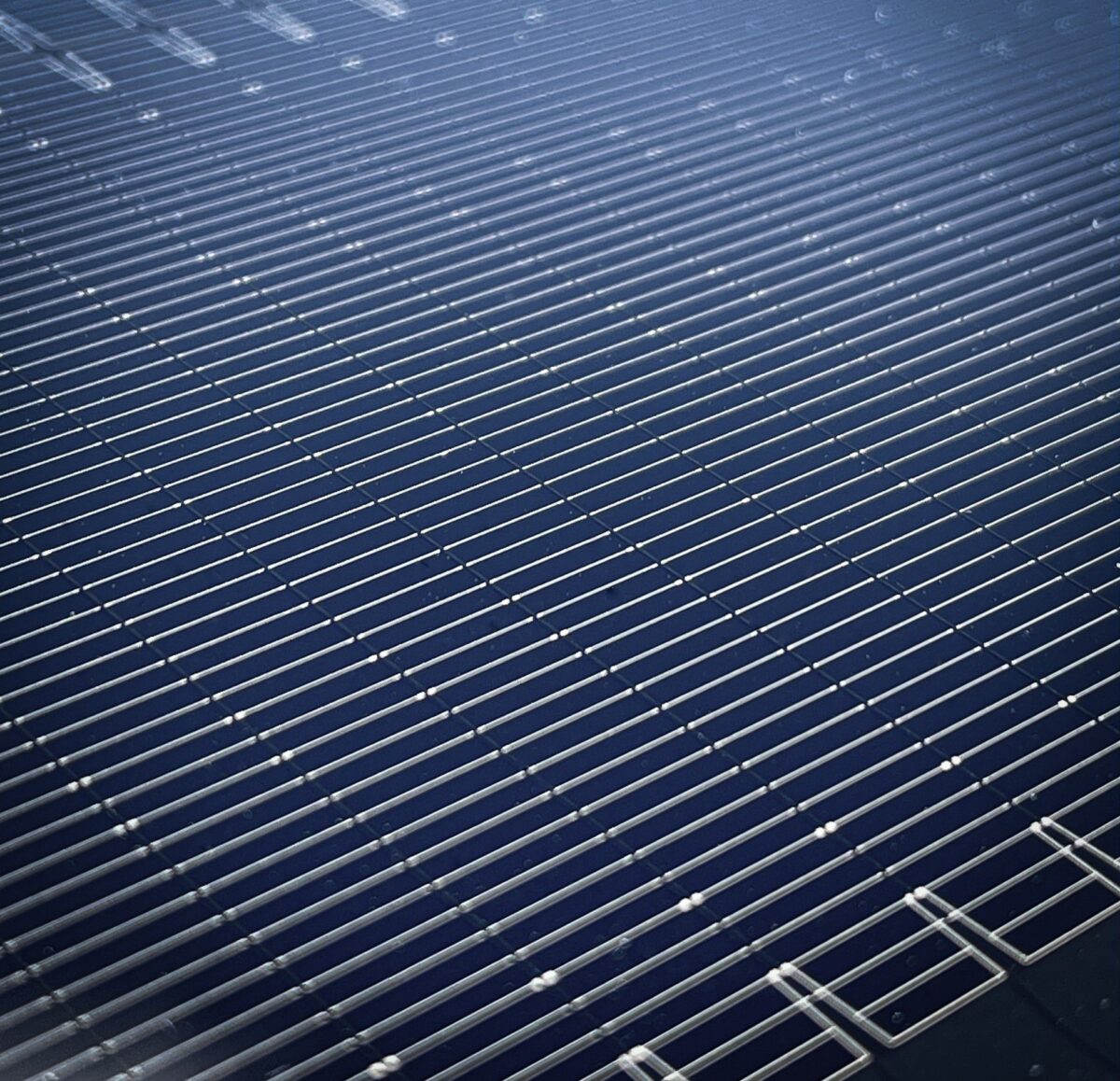

Called Thermoplastic and Electrically Conductive Coating (TECC-Connect), the proposed technology consists of a round copper core with a diameter of 210 μm that is covered by a very thin layer of silver for corrosion protection and then surrounded by a 20 μm coating of an electrically conductive thermoplastic.

It is implemented through a process that is similar to multibusbar technology, in which cables are coated with an electrically conductive thermoplastic instead of a solder alloy. With this approach, however, the cables can be processed with a slightly modified commercial stringer, with the melting point of the coating being engineered in a range between 130 C and 180 C.

With different chemistries of the coating, a wide variation in process temperature can be achieved, and the material can be engineered for the respective type of solar cell. The melting temperature of the coating can be adjusted, by using different thermoplastics for the wire coating.

According to Solyco, there is no limitation to the number of wires used per solar cell. Furthermore, no solderable electrical contact

surface, busbars and flux are required in the manufacturing step.

“With TECC, we achieve material independence from silver and enable full Restriction of Hazardous Substances (RoHS) compliance,” Lars Podlowski, Managing Director and CTO of Solyco, said.

According to Solyco, the elimination of silver reduces material costs in module production by up to 10%. “TECC-Connect is ideal for high-efficiency solar cells such as heterojunction (HJT) and tandem perovskite solar cells,” Podlowski said.

The first industrially manufactured TECC Connect solar modules will be presented at Intersolar, Munich, Germany, in May. The HJT modules are composed of cells that are connected with copper plating instead of silver fingers, according to Podlowski.

The technology has passed all standard quality and durability tests, according to Solyco. The company is currently working with several unspecified industry partners to scale up industrial mass production and launch the first products in 2026.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.