Researchers at Vidyasirimedhi Institute of Science and Technology (VISTEC) in Thailand have demonstrated a passive cooling material to address heat-related silicon PV output losses.

“We produced a passive cooling system requiring significantly less material but producing very high cooling capacity and cooling power compared with the benchmarks. Our hydrogel design has a thermoresponsive polymer as the main network, interlaced with another polymer which is hydrophilic,” Pichaya Pattanasattayavong, corresponding author of the research, told pv magazine.

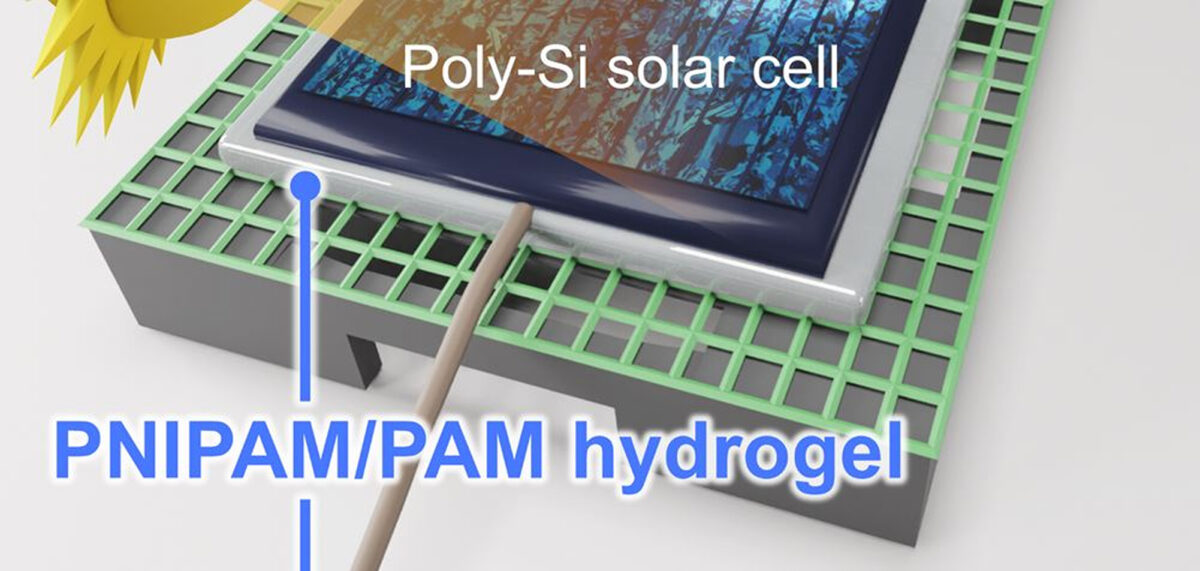

The hydrogel is described as thermoresponsive poly(N-isopropylacrylamide) (PNIPAM) semi-interpenetrating polymer networks (semi-IPNs) containing poly(vinyl alcohol) (PVA), poly(ethylene glycol) (PEG), or polyacrylamide (PAM).

“Crucially, the required weight for our optimized system, the 15 wt.% PNIPAM/PAM semi-IPN hydrogel, was only 5.14 kg m2, which is 80%-85% lower when compared to other examples,” said the researchers, making the point that its lower weight overcomes one of the drawbacks of phase change material (PCM) cooling.

The hydrogels were applied on the back side of metal sheets attached to 4.8 cm × 6.0 cm PV provided by UK-based Kitronik. Three setups were tested: a 15 wt.% PNIPAM/PAM sample, as it was the best performing in earlier experiments, a conventional PNIPAM hydrogel as the control sample, and bare solar cells.

The volume of the hydrogels was increased to match the dimensions of the solar cells and the higher temperatures attained during the heating period. The measurements of water release ratio and differential thermal analysis (DTA) revealed that the “cooling performance of hydrogels not only depends on how much water they absorb but also on how fast they can release water,” said the scientists.

The specific cooling power (SCP), which is noted as W g−1, was 1.86 W g−1. They added that by incorporating PAM into the thermoresponsive PNIPAM hydrogels to realize PNIPAM/PAM semi-interpenetrating polymer network hydrogels, a large swelling ratio (SR) of 30 was obtained. The optimal PNIPAM/PAM hydrogels also displayed a high water release ratio (WR), expelling 80% of absorbed water within 10 min. The optimal composition of PNIPAM/PAM hydrogels with 15 wt.% PAM was found to have the largest swelling ratio of 30 and the highest SCP of 1.86 W g−1.

The hydrogel system reportedly enabled a temperature drop of 23 C, from 70 to 47 C, and a relative 12.3% power conversion efficiency (PCE) increase compared to the reference device. “The most surprising was to see the drastic change in temperature of PV solar cells after having applied our material. Remarkably, 90% less material is required to achieve less than 20 C temperature reduction and over 12% increase in efficiency,” Pattanasattayavong said, noting that the control material saw a temperature reduction of 15 C, yielding an absolute increase in the PCE of 0.9%, and a relative increase of 7.4%.

Their findings are available in “A lightweight hydrogel system for passive cooling of solar cells,” recently published in Advanced Materials Technologies.

“We have received highly positive feedback from our industrial partners who are interested in upgrading the technology readiness level of our findings towards practical deployment,” said Pattanasattayavong. “On one hand, we would like to better understand the relationship between the material structure, cooling rate and cooling power. On the other hand, we are working on designing an efficient, practical process to produce and apply a layer of our material on the back of PV cells.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.