A research group led by Spain's Centre for Energy, Environmental and Technological Research (Ciemat) has investigated various aspects of ribbon interruptions in PV modules and has proposed a classification based on their type and location.

The work was done on modules where each cell is connected with two ribbons. While a previous work had focused on cases of twin interruptions, where both sides are impacted, the most recent work emphasizes the cases of single interruptions.

“It has been shown that second-hand photovoltaic panels can function satisfactorily after being repaired. One of the most frequent breakdowns of photovoltaic modules, constituting around 10% of the causes of failure, is caused by interruptions of the conductive strip located between two cells,” the team said. “A key aspect for repairing module interruptions must be the development of simple and low-cost techniques, so that there is an economic advantage of the repair compared to direct recycling.”

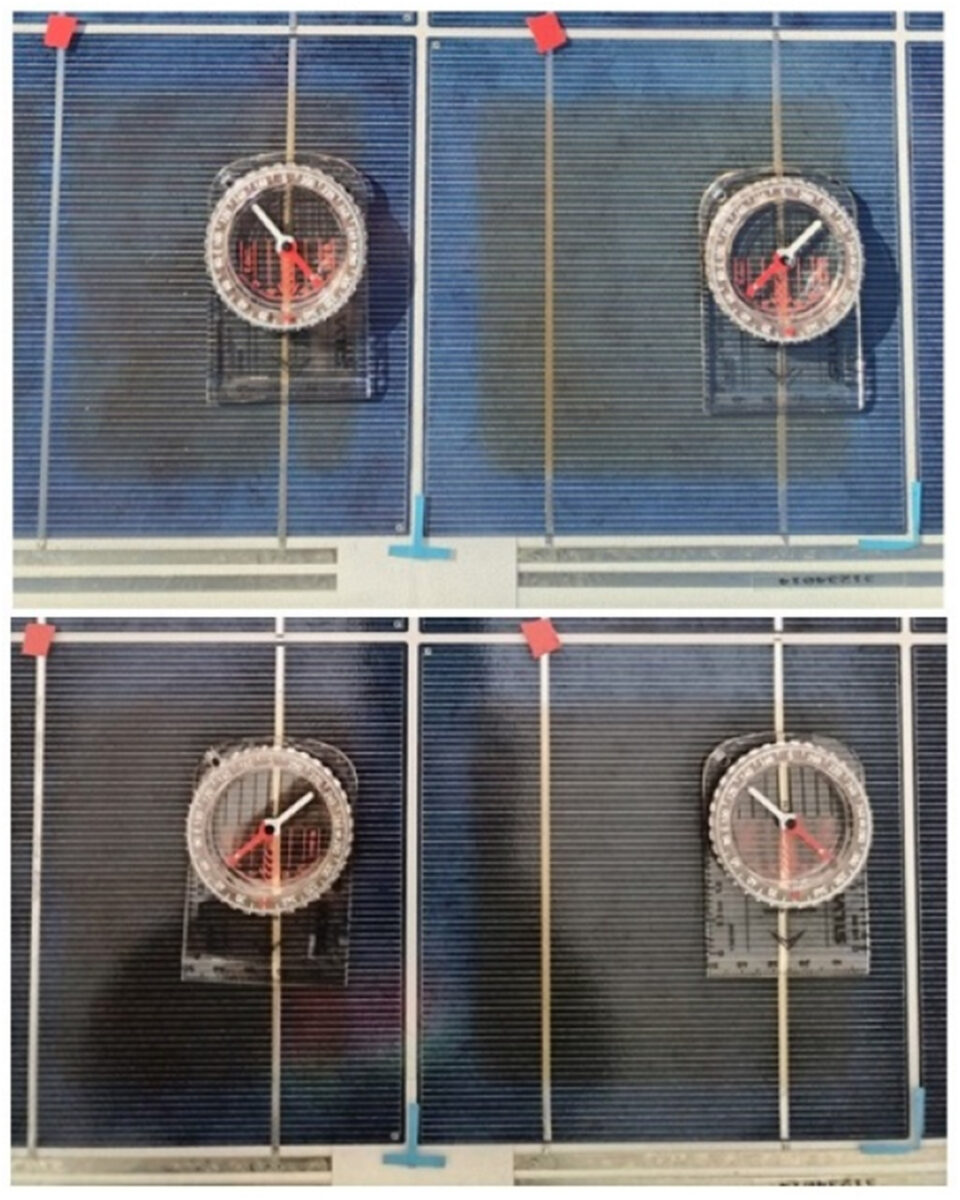

The scientists started by comparing different types of single interruption detection methods. The first method utilizes electroluminescence (EL) imaging, taking a picture of the light-emitting module in the dark. The second method uses an anisotropic magneto resistance (AMR) magnetic sensor moving along the ribbons, to look for sudden drops in the magnetic field. The third method uses a simple compass. As the current of the PV generates a magnetic field that deviates the needle, an area where it relapses to the natural direction suggests interruption.

The compression also included a detection method of twin interruptions, which was developed in an earlier work of the group. It uses a tone detector sensor, which emits an audible signal as long as there is electrical continuity in the ribbons. All four methods were tested on four faulty PV modules with a maximum power of 215 W.

Image: CIEMAT, Renewable Energy, CC BY 4.0

“The proposed method that makes use of a magnetic compass shows results that fully coincide with that of EL images and results obtained using two types of electronic current locators,” the academics noted. “The use of an AMR sensor has been demonstrated for the location of single interruptions, which can be used as a portable instrument in real installations under normal module operating conditions. In addition to locating single interruptions, this device allows numerical characterization of ribbon currents, as well as mapping the currents on the surface of the cells.”

The next step of the investigation was to classify the ribbon interruption on a more precise level than only twin or single. Two more classes were identified, namely delayed single interruption and delayed twin interruption. The first refers to a new single interruption that appears after repairing a previous single interruption; while the latter occurs when a second interruption appears in the same cell where a delayed single interruption already happened.

The researchers found that repairing twin interruptions recovers large values of lost power, with single interruptions recovering up to 6% more than the situation reached after repairing the twin interruptions. “For the modules analyzed, repairing all interruptions increased the generated power by up to 320%,” the group stated “In the modules analyzed, repairing all, (twin and single) interruptions permit an improvement of up to 25% in module fill factor.”

The results of the testing were presented in “Advances in the location and repairing of ribbon interruptions in photovoltaic modules,” published in Renewable Energy. Researchers from Belgium's imec and the country's office of BP Solar have also participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.