A research team from the University of New South Wales (UNSW) and Chinese solar module maker Longi has investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure and has found that the silicon nitride (SiNx ) layer on the cell rear-side is particularly vulnerable to chemical degradation from sodium (Na) contaminants.

“This topic has not received much attention to date but is a serious concern now that the stability of front metallization has improved,” the research's corresponding author, Bram Hoex, told pv magazine.

In the paper “Mitigating contaminant-induced surface degradation in TOPCon solar cells: Mechanisms, impacts, and mitigation,” which was recently published in Solar Energy Materials and Solar Cells, Hoex and his colleagues explained that SiNx rear-side vulnerability can lead to significant losses of open-circuit voltage, substantial resistance increase, and overall cell performance degradation.

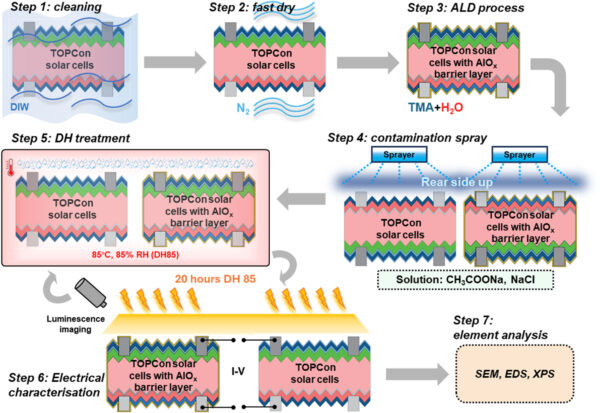

The researchers used several Na-related salts to investigate open-circuit voltage degradation in TOPCon solar cells under cell-level damp-heat (DH) testing. The DH test is an accelerated test that tests the reliability of modules under extreme humidity and heat. In its standard form, the PV is placed in a controlled chamber with a temperature of 85 C and humidity of 85% for at least 1,000 h.

The tests were conducted on commercial types of 23%-efficient TOPCon cells. On the front side, the devices featured a boron-diffused emitter, passivated by a multilayer stack of aluminum oxide (AlOx), a SiNx layer, and a silicon oxynitride (SiOyNz) layer as an antireflection coating (ARC).

On the rear side, the cells had a tunneling silicon oxide (SiO2) layer, a phosphorus-doped polycrystalline silicon (poly-Si) layer, and an additional SiNx ARC layer. Furthermore, the front side was treated with silver (Ag) and aluminum (Al), while the rear-side contact was formed using a screen-printed Ag paste.

Image: UNSW, Solar Energy Materials and Solar Cells, CC BY 4.0

The HD testing was conducted for 20 h in an ASLi environmental chamber at 85 C with 85% relative humidity (DH85). It showed that particularly two sodium contaminants – CH3COONa and sodium chloride (NaCl) – were responsible for significant performance losses.

“In our experiments, the application of CH3COONa on the rear side of the TOPCon cells led to a substantial 16% loss in efficiency, while NaCl caused a 4.8% relative decrease,” the academics stated. “The rear-side SiNx layer was particularly susceptible to chemical reactions and surface degradation when exposed to sodium-based salts, resulting in increased oxidation, passivation loss, and a marked reduction in key performance parameters, such as open-circuit voltage, with severe fill factor (FF) degradation when treated with CH3COONa.”

The analysis also showed that open-circuit voltage losses can reach up to 5.8%, with relative loss in overall cell efficiency being around 16%.

The research group proposed to address the analyzed degradation mechanisms by introducing on the cell front side a 10 nm aluminum oxide (AlOx) barrier layer, deposited via atomic layer deposition (ALD), to protect against contaminant diffusion.

“This layer effectively reduced performance degradation, demonstrating only minor decreases in efficiency and maintaining open-circuit voltage stability after 20 h of accelerated damp-heat testing,” it further explained. “The AlOx layer also mitigated corrosion and recombination defects induced by sodium-related salts, confirming its potential as a robust protective solution to enhance the long-term reliability of TOPCon solar cells under harsh environmental conditions.”

“Accelerated damp-heat testing confirmed that the AlOx layer significantly reduces degradation, maintaining long-term stability,” Hoex added. “Our solution represents a scalable and industrially viable approach for improving TOPCon solar cell reliability.”

Looking forward, the academics said they want to better integrate barrier layers in commercial production and analyze long-term degradation behaviors under real field conditions.

Previous research by UNSW showed the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.