From pv magazine France

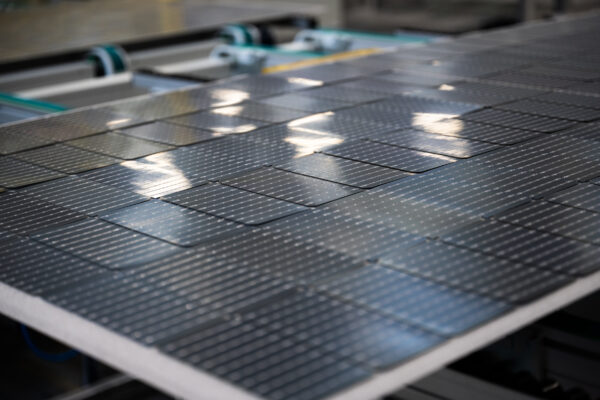

Reden Solar has opened a 200 MW solar module production line at its factory in Roquefort, Lot-et-Garonne, Nouvelle-Aquitaine, southwestern France.

The new line replaces a 65 MW production line that was installed 15 years ago, which had become outdated. The new line accommodates advancements such as 166 mm half-cells and 10 to 16 busbar connection points, replacing the earlier 72-cell modules with five busbars, said Tony Proutier, operations director at Reden Solar.

The company invested €4 million ($4.2 million) in the new equipment. Designed by Spanish manufacturer Mondragon, the modular line includes recustomized machinery from Eastern countries, particularly for cell welding. About 10 employees are needed to work on the line, producing up to 300,000 panels per year.

The factory manufactures mono passivated emitter and rear cell (PERC) panels with over 21.7% efficiency, rigorously tested for performance. The low-carbon-certified panels come in four ranges, from 405 W to 545 W, tailored for various applications like power plants, shade houses, and agrivoltaic systems.

Reden Solar Chairman and CEO Frank Demaille said that the company may eventually consider tunnel oxide passivated contact (TOPCon) technology.

“Our new production line will be able to adapt to it,” he told pv magazine France. “But TOPCon is only in its early stages, so it is better for us to have some perspective for its production.”

While the cells are manufactured in Asia, the copper comes from France and Belgium. The glass is from Austria and the EVA manufacturer is German.

“We are not passive when we buy panels or their components,” said Proutier. “We choose our raw materials to be transformed, by defining quality criteria with our partners and by carrying out on-site checks upstream. This is particularly the case for diodes, these small boxes that equip the modules and which are crucial for ensuring good connectivity.”

With Chinese solar panel prices falling, Reden Solar faces questions about the viability of producing its costlier modules in France.

“The additional cost is 50% to 70%, but the ‘panel' part of a solar power plant only accounts for one-quarter of the total price,” said Demaille.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.