Though perovskite solar cells have proved their potential in a plethora of lab experiments over the past decade, scaling these achievements up into mass production is something else entirely, and as a new technology, plenty of unanswered questions remain for perovskites in a commercial setting.

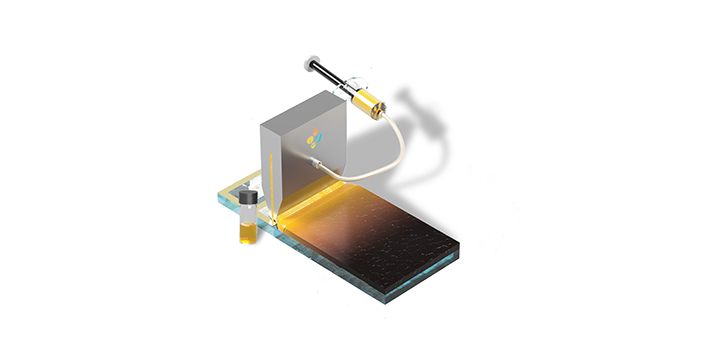

Slot-die coating (SDC), a process already used in various industries where an ink is pushed through a narrow slot as it moves across a substrate to form a continuous film, is among several techniques being investigated for perovskite solar cell production.

“As a community, we need to start looking at the stability and scalability of PSC technology,” explains Anand Subbiah, a postdoc researcher at Saudi Arabia’s King Abdullah University of Science and Technology (KAUST). “This high-throughput technique would allow for roll-to-roll fabrication, similar to printing newspapers.”

A group at KAUST investigated slot-die coating processes, aiming to develop a suitable perovskite ink for deposition onto a substrate. They developed a process coating substrates with the ink at a head speed of 15mm per second and a temperature of 70 degrees Celsius. These cells are then annealed at 100 degrees Celsius for several minutes.

Hydrophobic

The biggest challenge they found was that a material commonly used as a transport layer in perovskite cells, polytriarylamine (PTAA), is also hydrophobic and repellent to the liquid ink, leading to problems with film quality and at the interface between the film and PTAA layer. Adding a surfactant to the ink mix, lowering its surface tension, offered a solution to this.

Ultimately, the group fabricated perovskite solar cells that reached 21.8% efficiency. They also demonstrated that, with a few adaptations, the same process can deposit the perovskite ink directly onto textured silicon to form a tandem cell. In the paper High-Performance Perovskite Single Junction and Textured Perovskite/Silicon Tandem Solar Cells via Slot-Die-Coating, published in ACS Energy Letters, the group reports fabricating a perovskite/silicon tandem cell with 23.8% efficiency.

The group notes that there are still many more challenges to overcome in adapting such processes to large-scale production. The cells described in this paper are much smaller than commercial products (0.1cm² for the standalone perovskite cell and 1cm² for the tandem device), and covering larger areas while maintaining performance is not trivial.

“The development of scalable deposition techniques for perovskite solar cells is essential to bring this technology from the research labs to the market,” says KAUST associate professor Stefaan De Wolf. “Our next steps are making large-area devices and modules using our developed technology and testing their stability in the lab and the outdoors, while continuing to improve performance.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.