Researchers at France's National Solar Energy Institute (INES) – a division of the French Alternative Energies and Atomic Energy Commission (CEA) – have developed a new PV module interconnection technique based on the use of electrically conductive adhesives (ECA) with minimal silver (Ag) content, copper (Cu) ribbons and an Ag-Cu metallization paste.

“We evaluated three different ECA formulations ensuring their compatibility with ribbon coated by different conductive materials such as Ag, bare Cu, and tin mixed with silver,” the research's lead author, Rémi Monna, told pv magazine. “We found low-silver ECAs can outperform previous-generation ECAs demonstrating higher performance and reliability.”

In the study “Use of Cu ribbons and Cu-Ag HJT cell metallization on ECA-based interconnection for PV modules,” published in Solar Energy Materials and Solar Cells, Monna and his colleagues explained that their tests were conducted on a rear junction heterojunction (HJT) solar cell based on an M2 n-type Czochralski wafer and mini-modules with 8 half cells that were manufactured using Polyolefin Elastomer (POE) encapsulant.

The cell layers were deposited through stencil printing technology instead of screen printing technology. The former was chosen due to the advantages it offers for the reproducibility of the deposit over time, the researchers said. The modules were tested following the IEC 61215 standard in Damp Heat (DH) and Thermal Cycles (TC) aging.

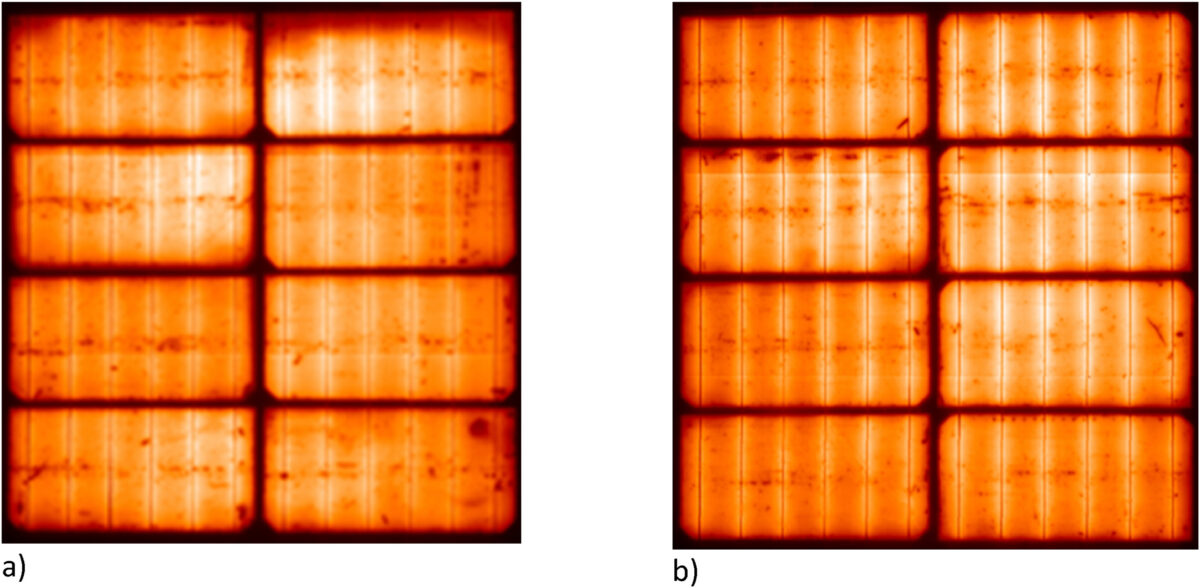

“Electrical parameters are measured after 100, 200, 400 and 600 TC with a specific focus on the fill factor of the module and electroluminescence imaging to reveal possible series resistance increase and interconnection failure,” the paper notes. “The peel test has been used to qualify the adhesion of interconnect ribbons to solar cell metallization.”

The analysis demonstrated that silver-based metallized cells and modules showed degradations below 2 % after 3000 h of DH, while in copper-based cells moisture degradation materializes after 2000 h, a value that the academics described as “similar” to that of modules with full silver metallized cells.

Furthermore, the scientists found that switching from Ag cell metallization to Ag-Cu metallization lowered the total silver quantity in the module, with a total silver amount of 14 mgAg/W being required. They also ascertained that silver use can be reduced by up to 26% when low Ag content ECAs are used in combination with bare Cu ribbons.

“We have conducted an initial, preliminary cost analysis. A more detailed study remains to be conducted in collaboration with our partners, taking into account the product characteristics, the planned production volumes, and other specific features of the industrial lines,” Monna explained. “Implementing this innovation requires joint work with equipment manufacturers, particularly for the screen printing and interconnection stages, as well as with material suppliers. The vast majority of these partners are based in Europe, which is an asset.”

Monna also stated that INES is currently planning to test this innovation in real production lines. “We are working closely with 3Sun on issues related to reducing the use of silver in modules,” he said. “Furthermore, some of the innovations we are developing can also be transferred to other cell technologies, and are therefore potentially of interest to other manufacturers.”

In January, INES and Italy-based heterojunction solar module manufacturer 3Sun, a unit of Enel, achieved a power conversion efficiency of 30.8% for a two-terminal tandem perovskite-silicon solar cell.

They also jointly developed DC/DC maximum power point trackers (MPPT) and achieved a power conversion efficiency rating of 24.47% for a gallium-doped p-type heterojunction silicon solar cell in March 2022.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.