A group of researchers led by the University of New South Wales (UNSW) in Australia has developed a tunnel oxide passivated contact (TOPCon) solar based on aluminum (Al) contacts placed on the rear side.

“The proposed cell configuration is aimed at replacing expensive silver (Ag) pastes used for cell contacts with low-cost aluminum, which can be seamlessly integrated into the existing industrial screen-printing infrastructure and is already well-established in solar cell manufacturing,” the research project's lead, Ning Song, told pv magazine, noting that Al pastes cost approximately $3–7/kg, which is more than 100 times cheaper than silver (Ag) pastes and significantly cheaper than emerging copper (Cu) pastes.

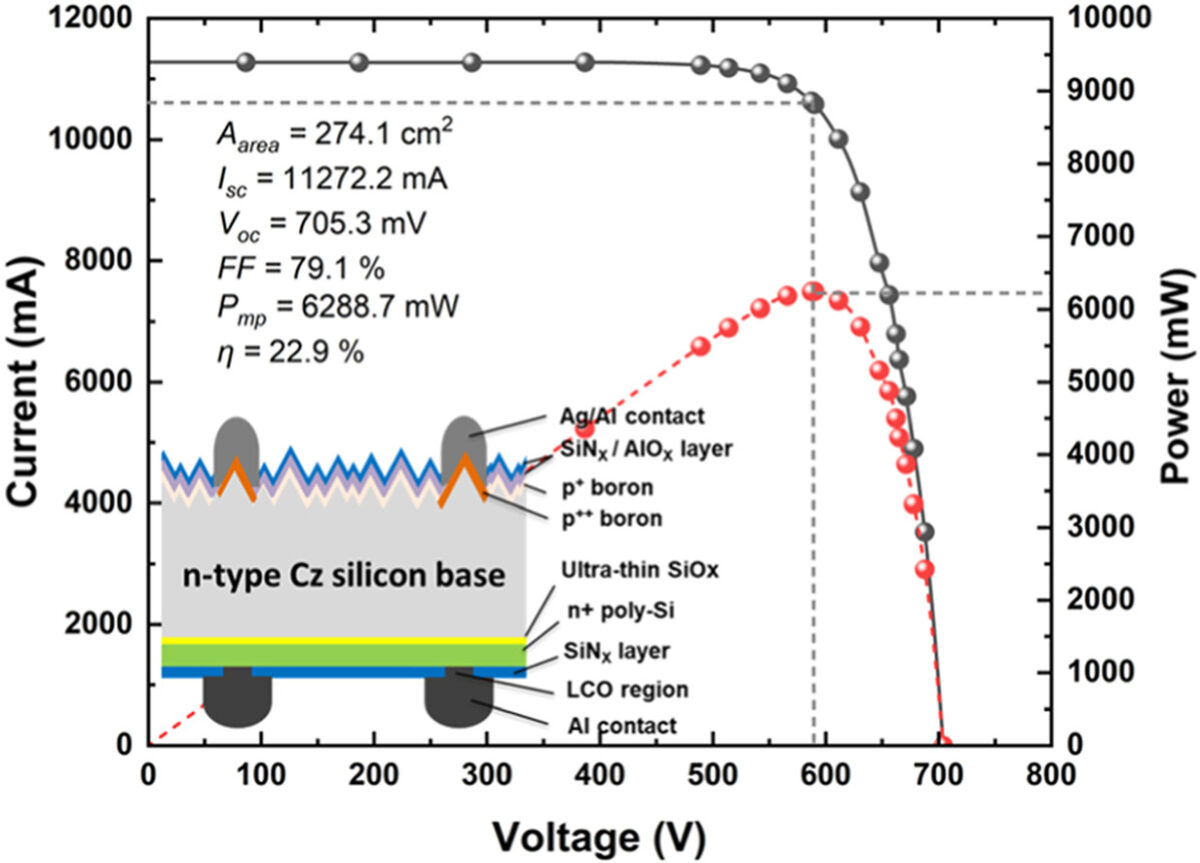

In the paper “Integration of aluminum contacts in TOPCon solar cells: A pathway to reduce silver usage,” published in Solar Energy Materials and Solar Cells, the scientists explained that they used Al contacts prepared with a laser contact opening (LCO) tool. The contacts were then screen-printed with a conventional Al paste provided by Japanese specialist Toyo Aluminum K.K.

“While the laser ablation step would involve some additional capex and opex, many manufacturers already operate laser contact opening (LCO) tools for PERC cell production. These tools can be repurposed for our process, making it both cost-effective and compatible with current manufacturing setups,” Song added.

The process was implemented without compromising the surface passivation quality of underlying silicon oxide (poly-Si/SiOx) layers and with the Al fingers being printed and fired with the aluminum paste on the rear surface of the cells. “Although the Al particles penetrated deeply into the poly-Si layer, they did not reach the poly-Si/SiO2 interface, preserving the surface passivation,” they emphasized.

With this rear cell architecture, the research team built several TOPCon solar cell samples with a firing temperature of 680 C. The performance of these cells was then compared to that of reference TOPCon devices manufactured with Ag contacts and metallization.

“With the optimal firing condition and LCO pattern design, the fabricated rear-Al champion cell has reached a promising 22.9% efficiency within a 0.8% efficiency gap with the rear-Ag reference cell,” the team stated. “Our findings highlight the necessity of minimizing Al/poly-Si contact recombination and resistance losses to effectively reduce the efficiency gap with the reference cell.

Looking forward, Song said more efforts will be devoted to reducing the efficiency gap between aluminum and silver contacts. “That said, we are open to collaborations and see strong potential for partnerships with manufacturers interested in adopting more sustainable and cost-effective metallization solutions” she concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.