A Kuwait University research team compared the effects on perovskite film grain-size, crystallinity, surface roughness, defects, and related solar cell performance of helium and argon quenching gases to nitrogen. Nitrogen, it noted, is typically used as a low cost and large area compatible way of creating proper crystallization of the perovskite layer.

“I expected to see different initial power conversion efficiencies, but I was very surprised to see that using inert gases with different molecular weight leads to altering of the operational lifetime of the solar cell as well,” Afshin Hadipour, corresponding author of the research, told pv magazine.

Indeed, the study demonstrated that perovskite films quenched with helium, as the lightest gas, and argon, as the heaviest, had larger grain sizes and were “very stable” under operational conditions compared to a device processed by nitrogen gas, which had a smaller grain size.

Characterization of surface effects, crystal size and grain formation was done via scanning electron microscopy (SEM), atomic-force microscopy (AFM) and post annealing x-ray diffraction (XRD). Further testing involved solar simulation inside a nitrogen filled glove box and opto-electronic tests that included photoluminescent (PL), external quantum efficiency (EQE) and time-resolved photoluminescent (TRPL) spectroscopy measurements.

“Average lifetime weights of three perovskite layers quenched with three different gases were compared with the longest exciton lifetime for film quenched with helium gas followed by nitrogen and argon gases, respectively,” noted the scientists.

They also noted that maximum power point (MPP) tracking results under illumination with 1 sun at 25C, the device quenched “with nitrogen gas is one order of magnitude less stable” compared to stable solar cell devices quenched with helium and argon.

Looking at the results of the testing sequences, Hadipour explained that while the devices made with all three gases started with similar power conversion efficiency (PCE) results of about 20%, there was a “huge difference” in solar cell lifetimes under operational conditions.

The perovskite active layers quenched with helium and argon had almost no degradation, exhibiting a PCE similar to the initial power conversion performance, “while the device quenched with nitrogen was left with only about 50% of its initial efficiency.”

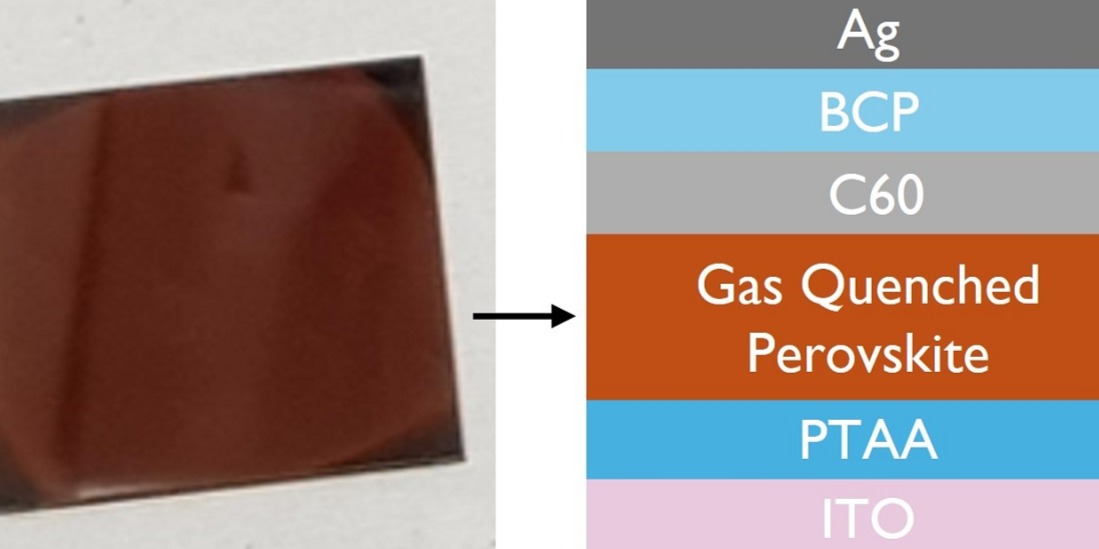

The devices used in the experiment were inverted p-i-n type devices with glass substrates measuring 9 cm2, and based on a formamidinium-cesium (FA-Cs) dual cation perovskite recipe with a 1.6 eV bandgap. In an n-i-p solar cell, the device is illuminated through the electron-transport layer (ETL) side, while a p-i-n structure is illuminated through the hole transport (HTL) surface.

The stack was as follows: indium tin oxide (ITO), polymer hole transport layer made of poly(triarylamine) (PTAA), gas quenched perovskite, buckminsterfullerene (C60) electron transport layer (ETL), a bathocuproine (BCP) buffer layer, and silver (AG) electrode.

The team asserted that the alternative quenching method is compatible with a variety of coating tools and has potential at large scale for production purposes.

“Of course, for each type of perovskite composition and precursor solvent, different inert gases must be tested and compared with each other to find the optimum quenching condition for each individual case,” it added.

The research collaboration with the researchers at Belgian research institute imec, according to Hadipour. It is described in “Enhancing gas-quenching method for fabrication of perovskite-based photovoltaics,” in the Kuwait Journal of Science.

The group will focus in the future on gas quenching of a variety perovskite compositions and with different solvent systems.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.