Researchers from Belgian research center imec and the University of Cyprus have announced completing outdoor stability tests of perovskite solar mini-modules providing two-year data on stability.

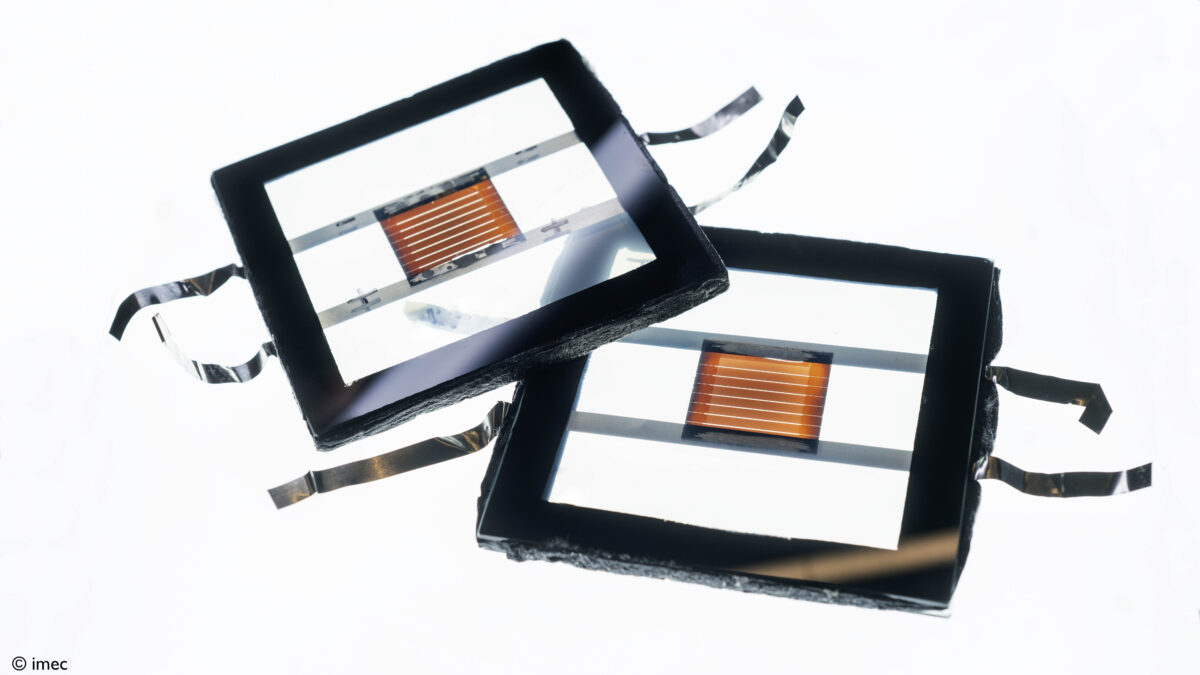

The research team tested 4 cm2 metal halide perovskite mini-modules, which were developed at imec/EnergyVille at Hasselt University in Belgium, under real-world conditions in Nicosia, Cyprus, and found that the panel offers “remarkable” power conversion efficiency retention after one year.

“The most durable mini-module maintained 78% of its initial efficiency after one year. Performance loss rates during the burn-in period of perovskites were found to be around 7% – 8% per month for the perovskite configurations tested,” said the researchers. They also captured diurnal degradation and recovery data, which was tracked across all the perovskite configurations tested.

“The results have also been disseminated and discussed at conferences and with our partners in different projects, which comprise both academia and industry. There is high interest since the data sets are some of the most extensive ones currently available for outdoor testing of perovskite modules,” Tom Aernouts, R&D Manager at imec/UHasselt/EnergyVille, told pv magazine.

Outdoor trials are steps toward the commercialization of perovskite technologies in utility-scale and residential PV applications as they reveal how environmental conditions, such as varying light, temperature and weather, affect cell performance. “Despite this, only a handful of research groups have investigated the outdoor performance of perovskite PV, focusing primarily on small cells rather than modules,” stated the researchers.

Further field trials are underway in diverse climate zones in Brussels, Madrid, Spain, Freiburg, Germany, and the U.S. state of New Mexico, which are rainy, moderate and arid regions, respectively.

“We also introduced some new perovskite module architectures for some of these tests, and we will continue to do so, also on new locations,” said Arnouts, mentioning Colorado, Middle East, North Africa and East Asia.

The perovskite mini-modules deployed in the study had a p-i-n device architecture, according to the researchers. The cells were built with indium tin oxide (ITO) coated glass substrates, sputtered nickel(II) oxide (NiOx) hole transport layer (HTL), perovskite layer, electron transport layer (ETL) and another ITO layer. The perovskite composition for the research was FA0.8Cs0.2Pb(I0.94Br0.06)3. The ETL composition was varied, either lithium fluoride (LiF), buckminsterfullerene (C60) and a bathocuproine (BCP) buffer layer or the LiF/C60/LiF composition.

The field measurements, which had “an emphasis on the evolution of key electrical parameters,” were acquired with a variety of electrical equipment from commercial suppliers, and a weather station, including a single current-voltage source-meter multiplexed to take sequential measurements from the devices under test. In addition, LabVIEW software was designed to record the current−voltage (I−V) curves every 10−15 min.

The data gathered enabled the scientists to develop a data-driven predictive model to predict the power output time series using the eXtreme Gradient Boosting (XGBoost) regression technique. They noted it could “accurately” forecast the power output of the test set with a 6.76% normalized root mean squared error (nRMSE), which means it demonstrated “a strong correlation between the actual and predicted power.”

The most challenging aspect of the study, according to Aernouts, was the reproducibility of the sample fabrication process, which he noted is “crucial for the relevancy” of outdoor testing.

“Therefore, we developed a highly reproducible module processing baseline first, including strong encapsulation. This also meant that long service life for full modules got priority over one-time small area single cell efficiency, said Aernouts, adding that another challenging aspect was that test locations need to adapt their setups for perovskite cell technology.

The research work is described in “Diurnal Changes and Machine Learning Analysis of Perovskite Modules Based on Two Years of Outdoor Monitoring,” in ACS Energy Letters.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.