Switch Technologies, a heavy-duty battery and electric vehicle engineering services supplier, has unveiled what it says is the world’s first operational vehicle powered by UK-based Echion Technologies’ proprietary ultra-fast charging XNO active anode material technology.

XNO enables lithium-ion batteries to safely fast charge in less than 10 minutes, maintain high energy densities even at extreme temperatures, and deliver high power across a cycle life of more than 10,000 cycles.

The material was specifically engineered to maximize productivity and minimize total ownership costs for electrified heavy-duty vehicles, such as the Toyota Land Cruiser 79 Series, demonstrated at the Australian Automation and Robotics Precinct (AARP) in Perth, Australia.

The Land Cruiser has been modified into a plug-in hybrid configuration and is equipped with cells manufactured by Li-FUN, an XNO cell development partner.

Echion Technologies said “powered by XNO” means lithium-ion batteries that can ultra-fast charge safely, maintain high energy densities even at low temperatures, and deliver high power across a cycle life of more than 10,000 cycles.

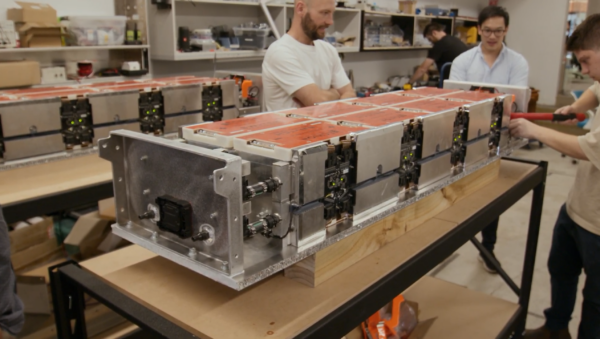

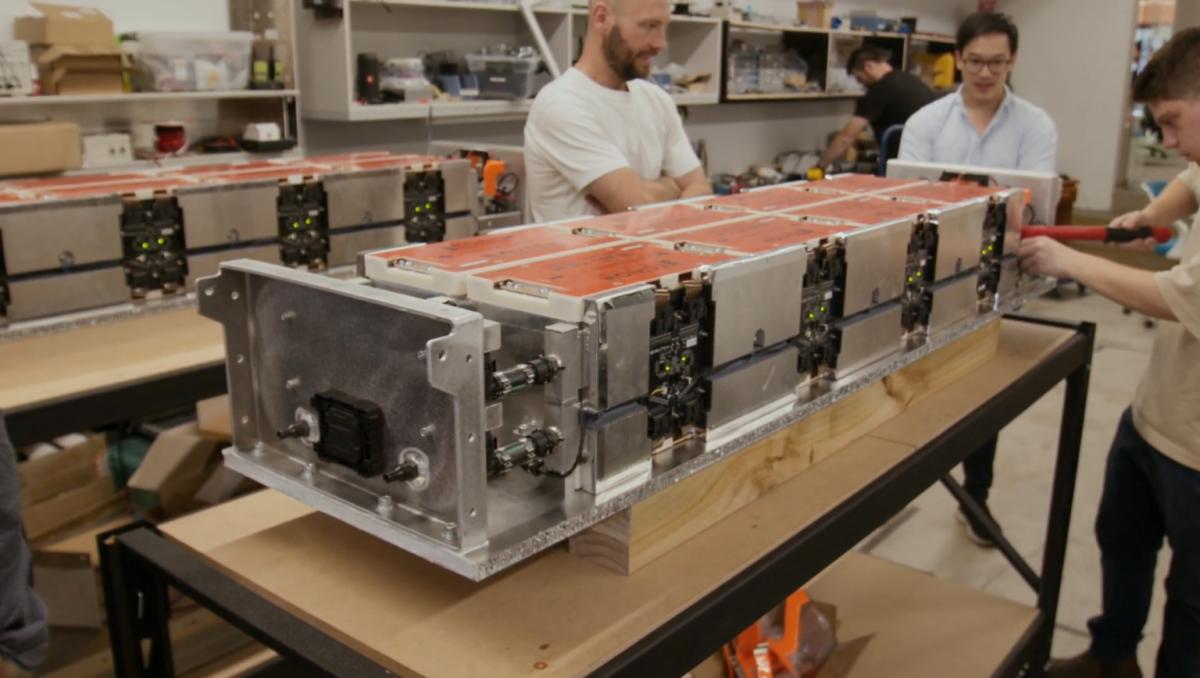

Over a nine-month period, Switch Technologies developed new XNO battery modules and packs, along with drivetrain modifications and control systems to hybridize the Land Cruiser. It has now begun a comprehensive test and validation program to further highlight the benefits that XNO anode materials bring for batteries used in heavy duty industries.

Switch Technologies CEO Jan Haak said whether it’s about removing diesel particulate from near people, reducing emissions in fleet, or boosting the performance of the existing machine, Switch is excited to scale this XNO-powered product into the market.

“We are delighted at the early feedback from customers as we’ve developed this machine to be supportable and reliable in harsh conditions as is expected of a typical off-road vehicle,” Haak said. “Mining customers are telling us that they’ll be able to operate the vehicle as a pure EV for a whole shift, with the confidence of a full range diesel machine should they need a longer trip and being able to fully charge in less than 10 minutes removes friction that operators experience with conventional EV systems on site.”

Echion’s XNO anode material is available at scale due to a partnership with Brazil-based niobium producer CBMM and the manufacturing facility the companies opened together, dedicated to producing up to 2,000 tons of niobium anode per year of XNO or the equivalent of 1 GWh of lithium-ion cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.