Scientists from Sophia University in Japan and Università di Pavia in Italy have developed a microwave-induced pyrolysis method to recycle VVF power cables.

The research paper “Recycling of e-waste power cables using microwave-induced pyrolysis – process characteristics and facile recovery of copper metal,” published in the journal RSC Advances, says electrical wiring cables, made up of copper or aluminum wires, are a significant waste problem despite being highly recyclable. It adds the recycling rate for PVC insulation material is currently only about 35%, with the majority ending up in landfills.

“VVF cables are commonly used as power cables in houses and buildings and have a high reuse value among e-waste,” said Satoshi Horikoshi, one of the study’s lead authors. “Our method is suitable for recycling and recovering e-waste containing metals and requires no pre-treatment to separate the plastics from the metals.”

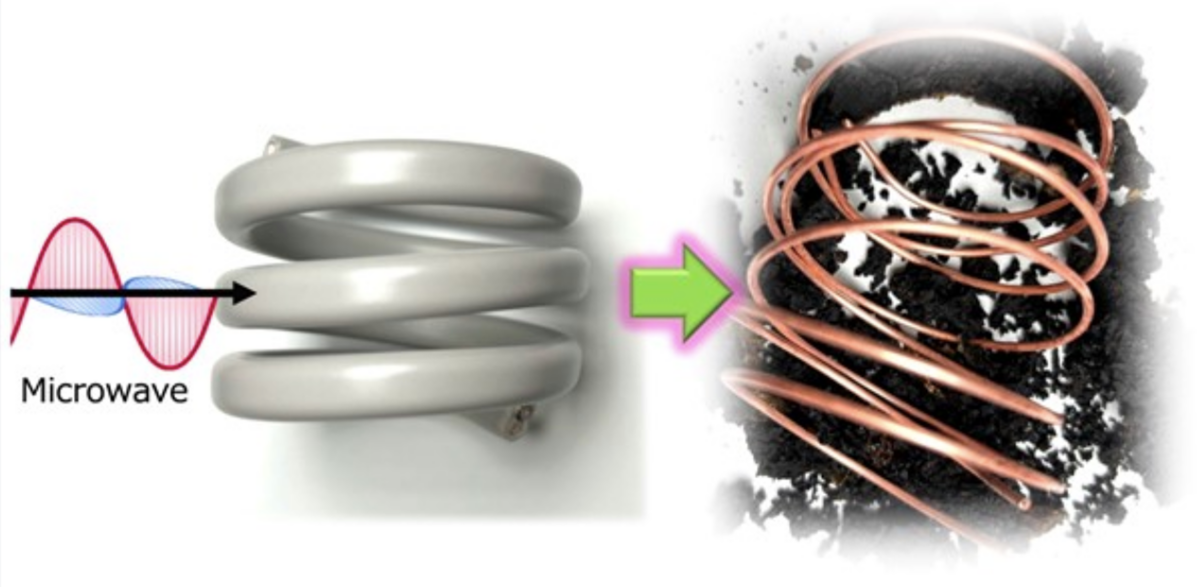

The method developed by the researchers involves placing VVF power cables in a glass reactor where they are subjected to microwave radiation. The pyrolysis carbonizes the PVC insulation, exposing the copper wire and allowing it to be easily recovered.

In the study, the researchers tested a standard 54 cm VVF cable and cut pieces of different cable lengths, of 1 cm, 6 cm, 9 cm, 12 cm, and 18 cm. The then exposed them to microwave radiation of 100, 200 and 300 W.

The team found the effectiveness of the pyrolysis varied with the cable length relative to the microwave’s wavelength, which was approximately 12.24 cm at a frequency of 2.45 GHz.

Pyrolysis was most effective in cables where the length matched specific fractions of the wavelength. The 9 cm, equal to about 3/4 wavelength, and 18 cm cables, longer than the wavelength, began pyrolyzing after 60 seconds at 100 W. The 3cm cable, equivalent to about 1/4 wavelength, started pyrolysis at 200 W.

Other lengths of 1 cm, 6 cm and 12 cm, which represented whole or nearly whole wavelengths, showed no pyrolysis at 300 W.

With the microwave demonstrating the capability of heating and breaking down wires longer than the wavelength, the 54 CM VVF cable proved to be entirely pyrolyzed in 12 minutes under 300 W radiation, leaving the copper wire intact and undamaged.

This was achieved without the generation or use of toxic chemicals. The researchers explain that during the pyrolysis, the PVC insulation underwent rapid dichlorination and carbonization, which prevented the formation of harmful byproducts such as tar, polycyclic aromatic hydrocarbons and dioxins.

“Clearly, microwave-induced pyrolysis has proven suitable for recycling/recovery of e-waste containing metals and requires no pre-treatment to separate the plastics from the metals,” the researchers said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.